About Us

Standard® is the leader in the automotive aftermarket. Backed by more than 100 years of experience, we design, engineer, manufacture and distribute over 60,000 of the highest-quality engine-management products in some of the most advanced technology categories. Our ignition and fuel-system components, sensors, switches, computerized engine controls and all of our other advanced engine systems parts all have one thing in common – we won’t let them leave our facilities until they meet our strict quality standards. That’s how we know that they’ll meet your high standards.

About Standard®

Standard® is the premier professional engine-management brand in the automotive aftermarket today. Standard® leads the way in advanced automotive technology with more than 60,000 products and provides complete coverage for domestic and import vehicles.

We manufacture and distribute a full line of high-technology critical components for the vehicle’s ignition, electrical, emission and fuel systems. Key categories include ignition coil-on-plugs, ignition wire, EGR valves and solenoids, fuel injectors and related components, airbag clock springs, power door lock actuators; switches, featuring multi-function, combination, cruise control, fog lamp, power seat memory, steering wheel audio, and more. Our evolving line of sensors includes camshaft and crankshaft, clone-able TPMS sensors, ABS speed, brake pad wear, brake fluid pressure, turbocharger boost, vehicle speed, YAW rate sensors and more.

That’s one reason that our Standard® brand enjoys tremendous recognition at the installer level – Standard® is the automotive standard!

Standard® Engineering

SMP's engineering and design capabilities are second to none. We have a large, dedicated, professional engineering team utilizing the following processes and methodology.

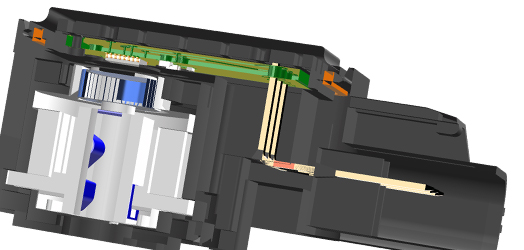

- 3D design modeling of product componentry, tooling, and complete manufacturing process

- CAD Electronic Circuit design

- Stress analysis modeling

- Magnetic FEA modeling

- Finite elemental analysis

- Fast Prototyping – SLA Stereolithography Analysis

- Digital Performance analysis

- Prototyping and extensive testing

- Custom circuit development

- 100% validation process

- 100% consistent product reliability

We have an extensive testing regimen and product validation that all of our products go through including:

- Vehicle Dynamometer

- Engine Dynamometer

- 5 Gas Analysis

- Vehicle Cold Chamber

- Vehicle Test Fleet

- Thermal Cycling

- Digital Output Analysis

- Durability

- Vibration

- Salt Spray/humidity

- Spray Pattern Analysis

- Air / Fluid Leakage

- Flow Test Stands (Multiple Fuels)

- Hot Injector Flow

Of course, with 60,000 parts in the line, we can’t make everything. However, we have the resources and experience to provide the engineering and quality control to ensure that all of the products that are placed in a Standard® box still means high-quality. Our Asian sourcing office includes a team in Hong Kong and Taiwan with sourcing and engineering expertise. This team receives significant LIC support with a dedicated Director of International Sourcing, a 20,000 sq. ft. laboratory and test facility, and a dedicated staff of engineers and engineering technicians to ensure excellent quality control.