-

What's In Your Box

- History, Trusted Brands & Training

- Manufacturing, Engineering & Testing

- Parts are Just Parts?

- ABS Speed Sensors

- ADAS

- Blower Motor Resistors

- Blue Streak Import Coils

- Blue Streak Kits

- Camshaft & Crankshaft Sensors

- Collision Repair Program

- Electronic Throttle Bodies

- EV / Hybrid Program

- EVAP Components

- Gas Fuel Injection

- GDI Injection

- Ignition Coils

- Oil Filter Housing Kits

- Oil Pressure Switches

- Parking Brake Actuators

- TPMS

- Turbocharger Kits

- Variable Valve Timing

- Resources

- Standard® and Blue Streak® offer more than 800 coils for 99% aftermarket-leading coverage.

- Every Standard® coil is subjected to extensive testing and product validation.

- Blue Streak® coils beat the OE with more spark energy and longer-lasting discharge for improved performance.

Because we’re an expert coil manufacturer, you know

what to expect every time you open our box.

Not every supplier can say the same.

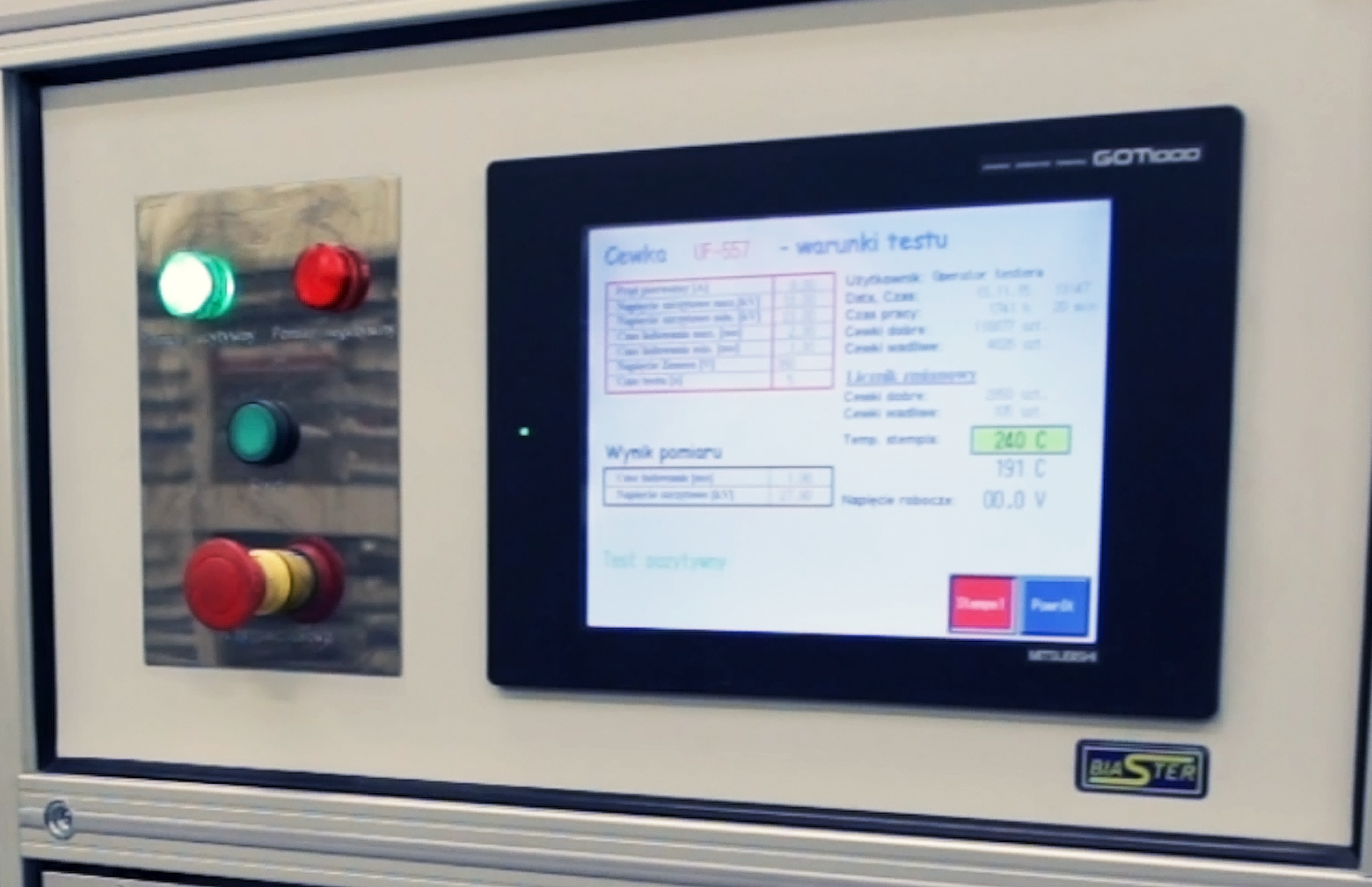

Ignition coils are manufactured at SMP Poland, an IATF 16949-certified design, engineering and manufacturing center. We produce over 6 million coils and release 110+ new products each year.

Superior Coil Engineering

Many suppliers are just product importers. That’s not who we are. It’s not enough to lead the market with 99% coverage. As an expert manufacturer, we study the OE platform coils to identify weak points in original coil designs that lead to failure. Then we engineer improvements to produce a more reliable coil.

Ignition Coil Testing

Our ignition coils undergo a full regimen of measurement and life tests, plus environmental analysis that includes thermal shocks, thermal cycling and vibration tests. You can install Standard® and Blue Streak® ignition coils with confidence, knowing they meet and often exceed the performance and durability of the original.

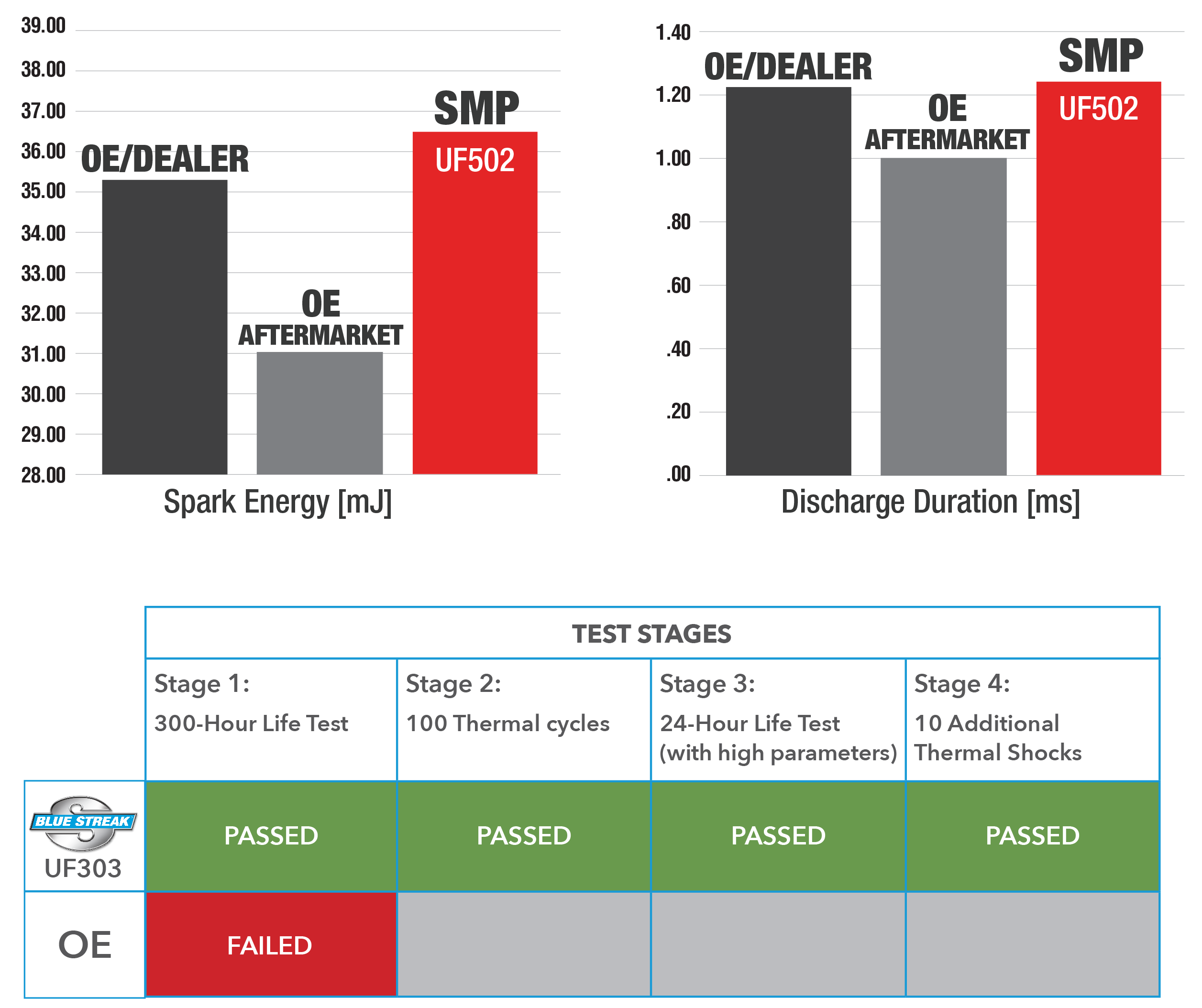

Blue Streak® Outperforms the OE

Testing Takeaways

Test 1: Blue Streak® coils outperform the OE and OE aftermarket coils with more spark energy and longer-lasting discharge to deliver improved performance and fuel economy.

Test 2: The OE coils short-circuited and never completed Stage 1. Blue Streak® coils passed 100 thermal cycles, a 24-hour life test, and 10 thermal shocks, producing more energy and higher secondary voltage for exceptional performance and durability.

Standard® – We Pay Attention to the Details

-

Engineered and tested to match or exceed OE for spark energy output, impedance and durability

-

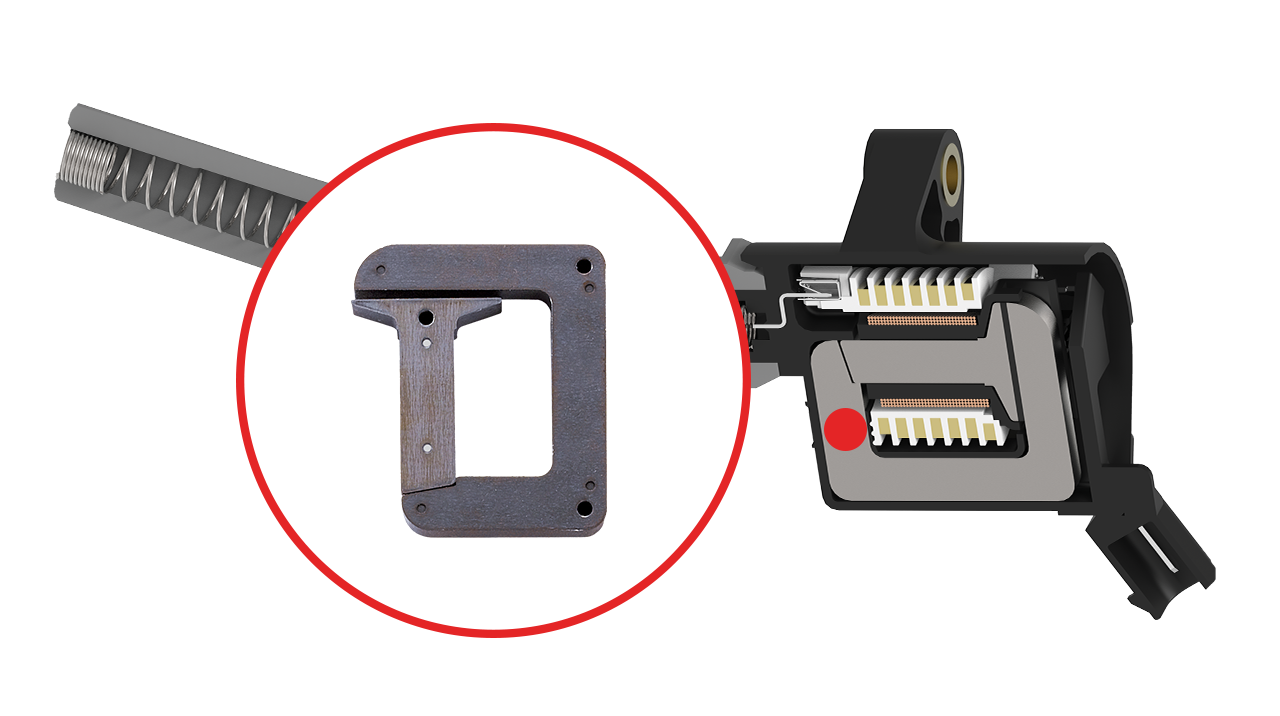

Boot and Spring Assembly

High-temp boot prevents high-voltage leaks, while stainless-steel spring with internal ferrite noise suppressor prevents RFI. -

Core

Internal neodymium permanent magnet maximizes high-voltage output at all speeds. -

Coil Housing

High-impact material bonds to epoxy to ensure a longer service life. -

Coil Connector

Advanced thermoplastics ensure proper connection and resist heat fractures. -

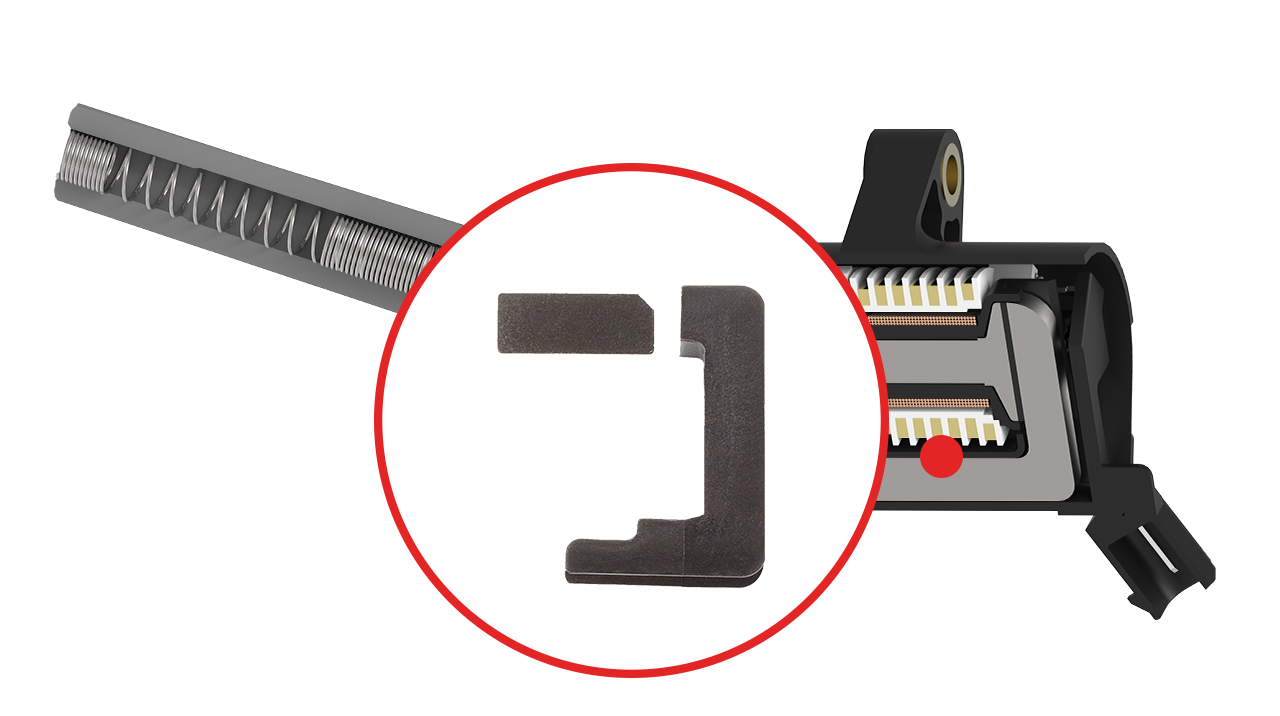

Isolator

High-voltage resistant thermoplastics prevent premature failure. -

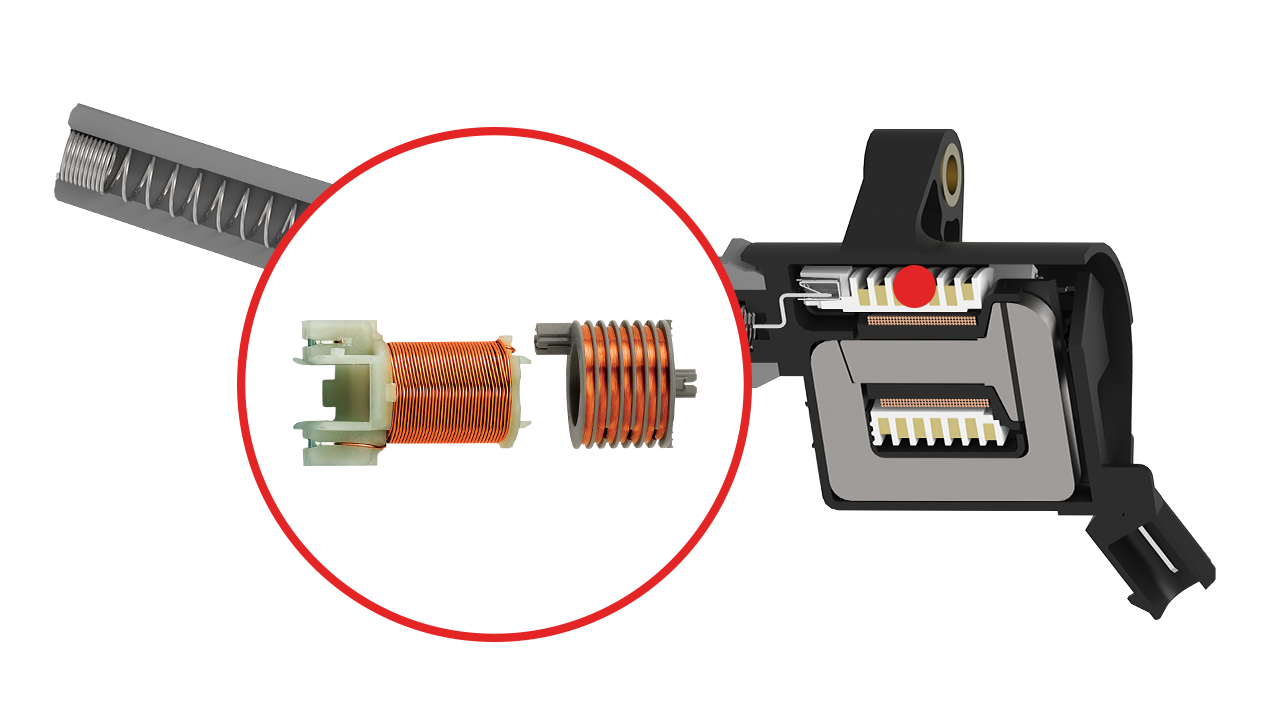

Primary and Secondary Bobbins with Winding

Copper-wound wire ensures high voltage for peak performance, while high-dielectric-strength bobbins prevent voltage flashover.

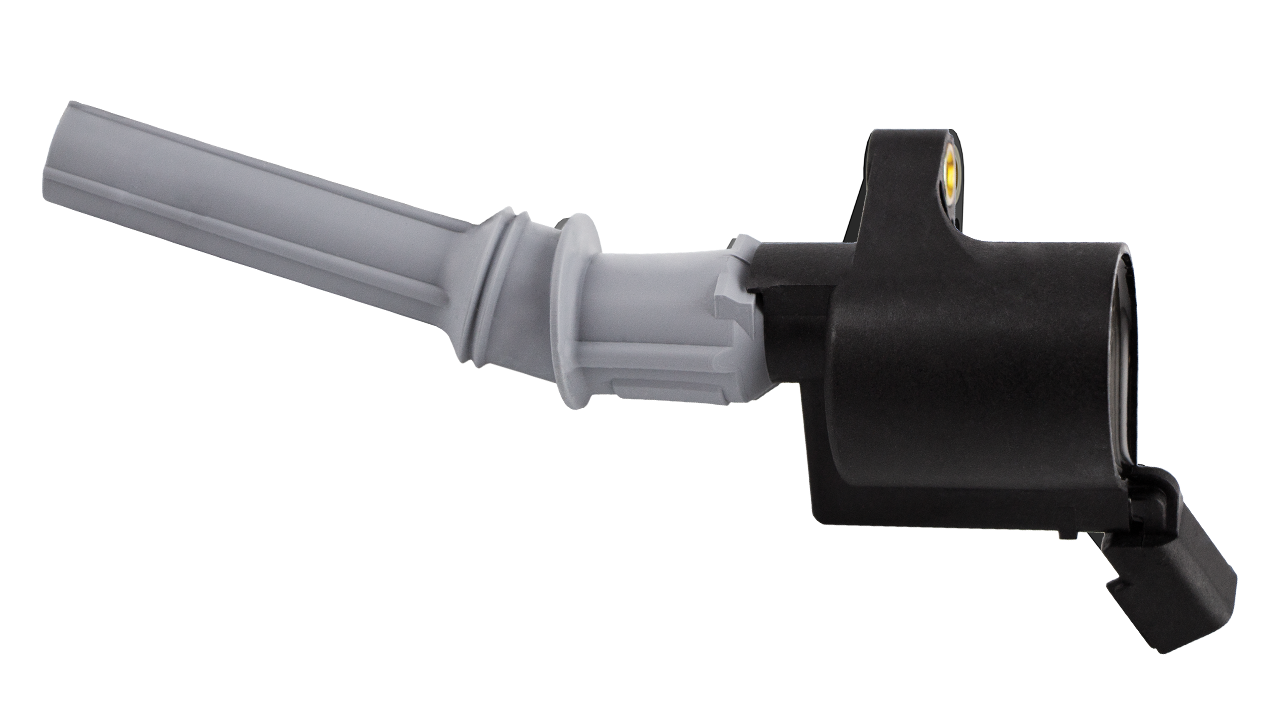

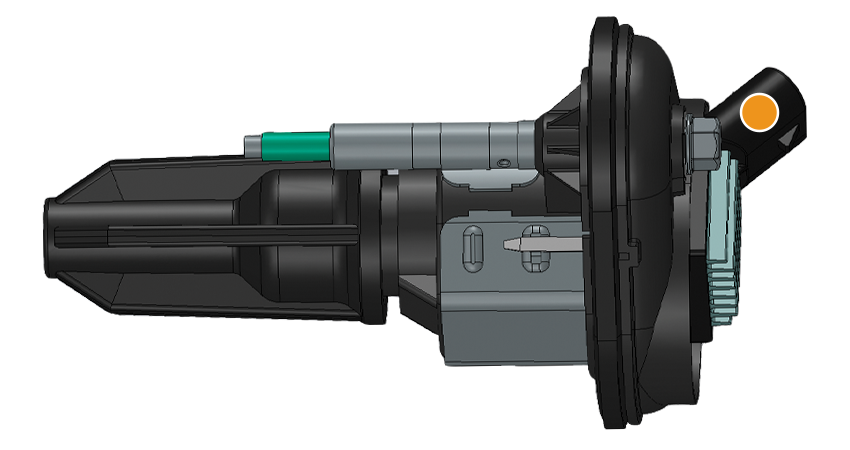

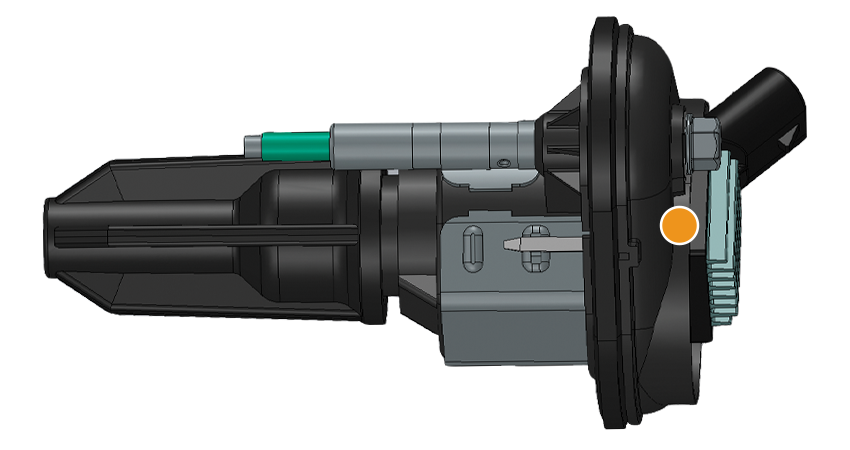

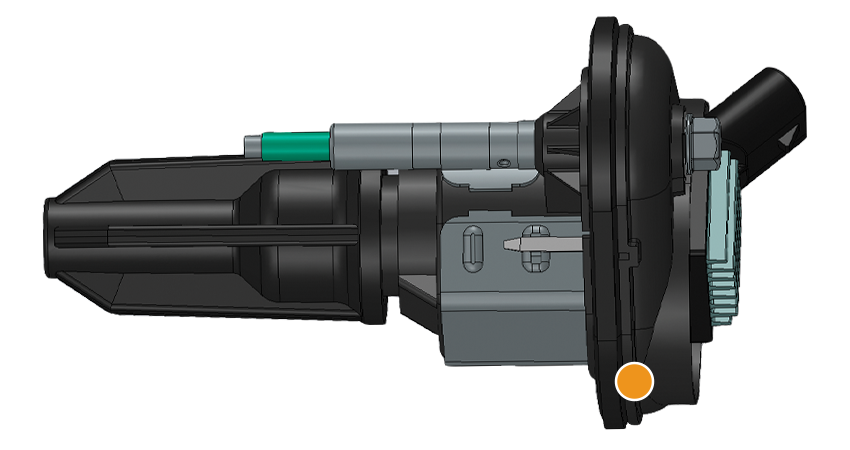

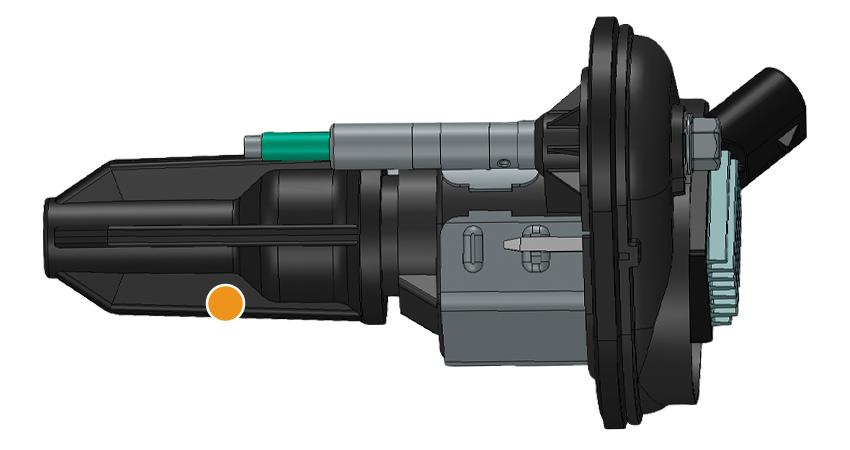

Blue Streak® – Product of Superior Design

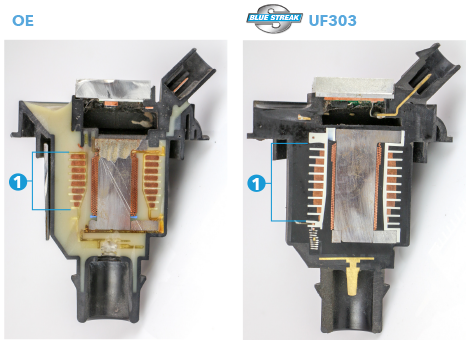

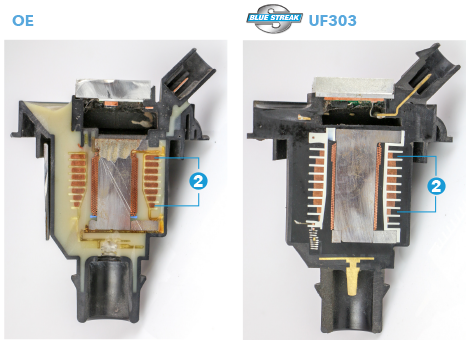

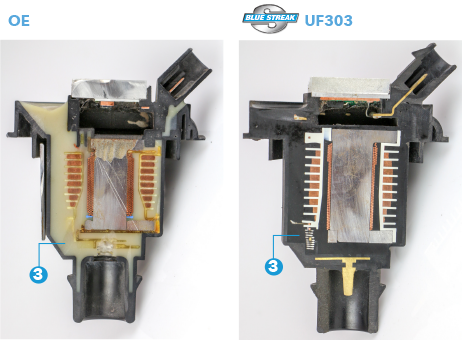

Blue Streak® heavier-duty ignition coils are the product of superior design, manufacturing and testing. For example, look at the features of our premium UF303 coil and how it improves on the original.

View our Blue Streak Just the Facts: Heavier-Duty Ignition Coil Flyer

-

Advanced thermoplastic coil connector ensures proper connection and resists fractures caused by heat and thermal cycling.

-

Primary (23 gauge) and Secondary (43 gauge) copper wire ensure high-voltage availability for peak performance, while reinforced bobbins prevent voltage flashover for extended service life.

-

High-impact housing material ensures superior bond to epoxy for longer life in all operating conditions.

-

Internal, neodymium permanent magnet core surrounded by grain-oriented, magnetic-laminated steel maximizes high-voltage output at all engine RPMs and loads.

-

Tested at extreme engine performance condition at 7200 RPM

-

Engineered and tested to match or exceed OE for spark energy output, impedance and durability.

-

High-temp boot prevents high-voltage leaks, while stainless-steel spring with internal ferrite noise suppressor prevents radio frequency interference (RFI).

-

Isolator manufactured using high-voltage-resistant thermoplastics to prevent premature coil failure

-

Copper wires using higher insulation grade ensure heat resistance and prevent high-voltage breakdown.

-

Optimum wire distribution developed by extensive testing ensures superior functional parameters and durability.

-

OE: 8 primary winding sections

Blue Streak: With 10 primary winding sections, our design reduces the height of each section’s winding to decrease the risk of breakage between sections.

-

OE: Uneven number of winding turns

Blue Streak: Our barrel-winding distribution precisely reduces the number of turns in the first and last two sections to reduce the voltage gradient. When combined with our higher G2 insulation grade, our winding distribution lowers the risk of breakage within the winding.

-

OE: Potted using “yellow” epoxy system.

Blue Streak: When compared to common “amber/yellow” epoxy systems, our “black” epoxy system features nearly 40% higher insulation resistance to voltage breakdown.

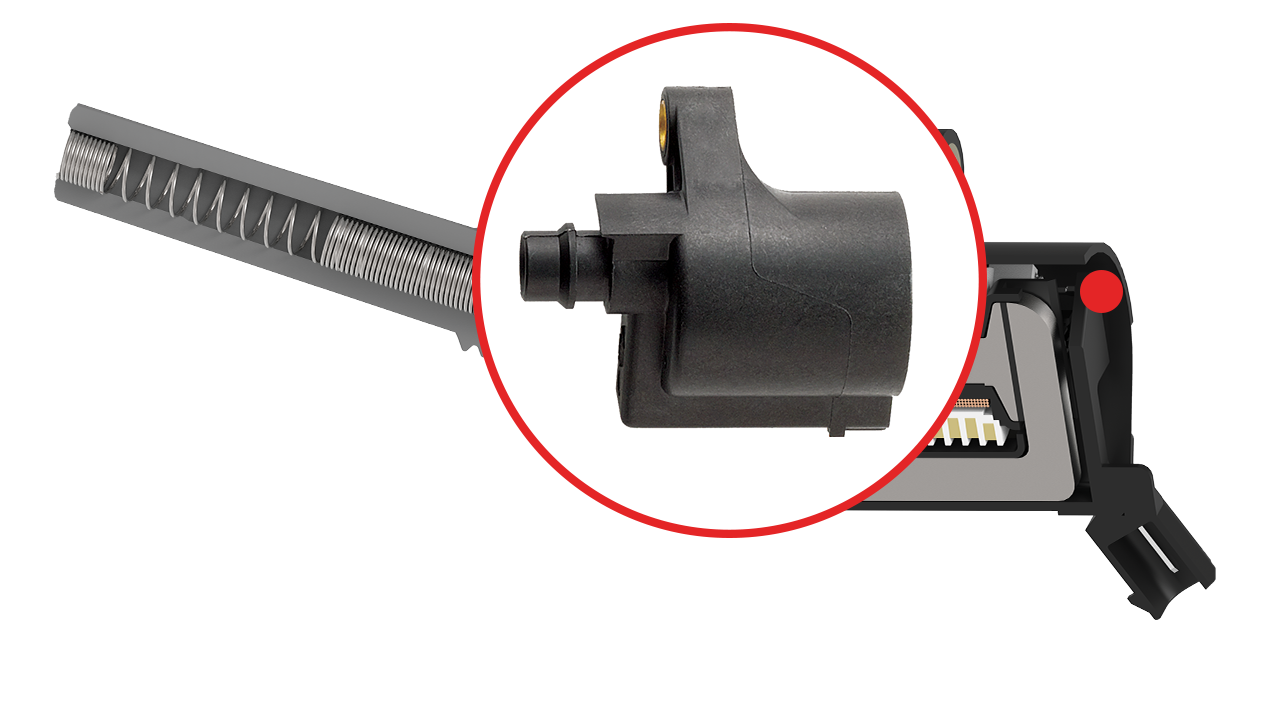

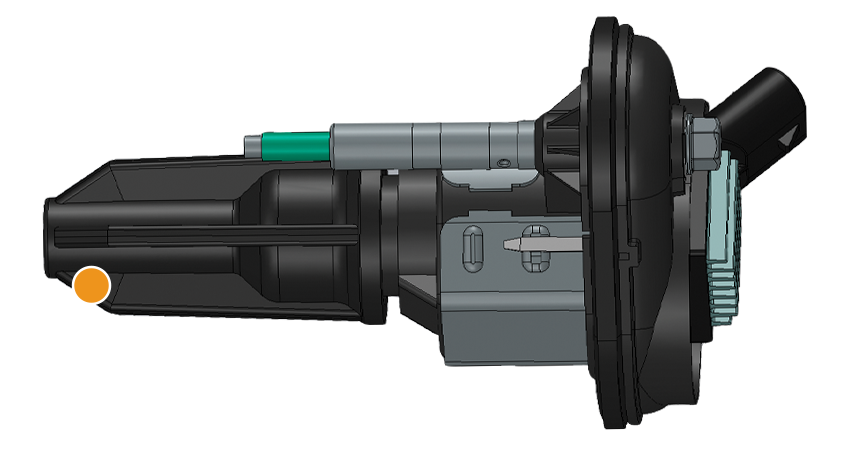

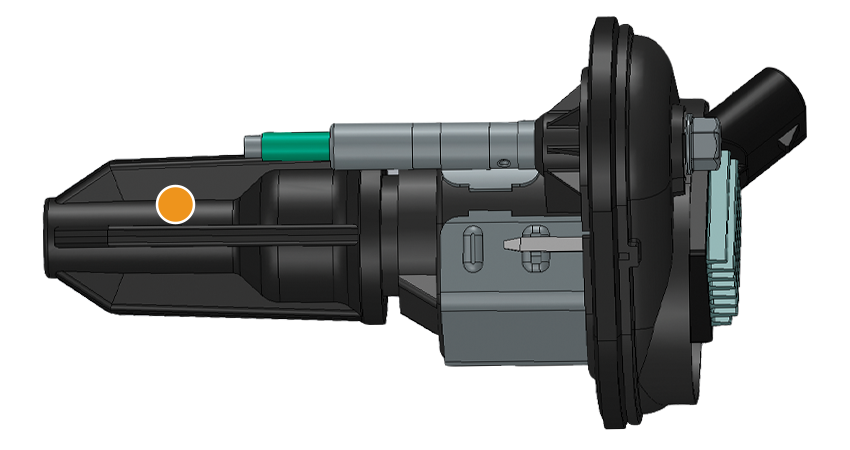

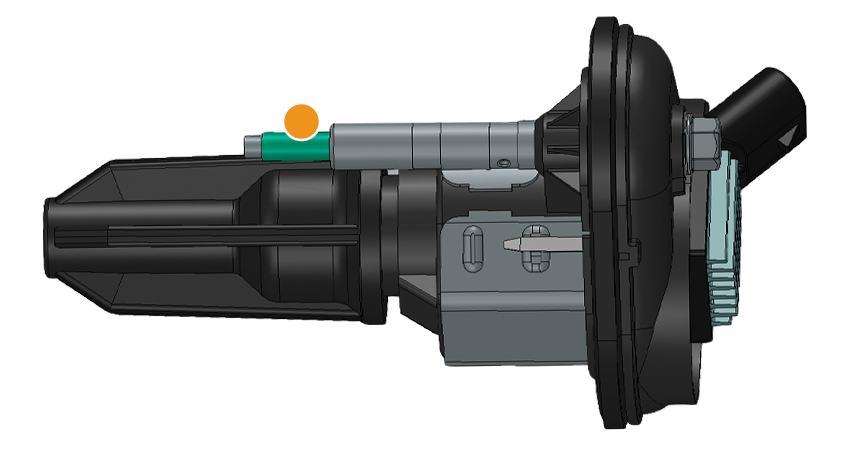

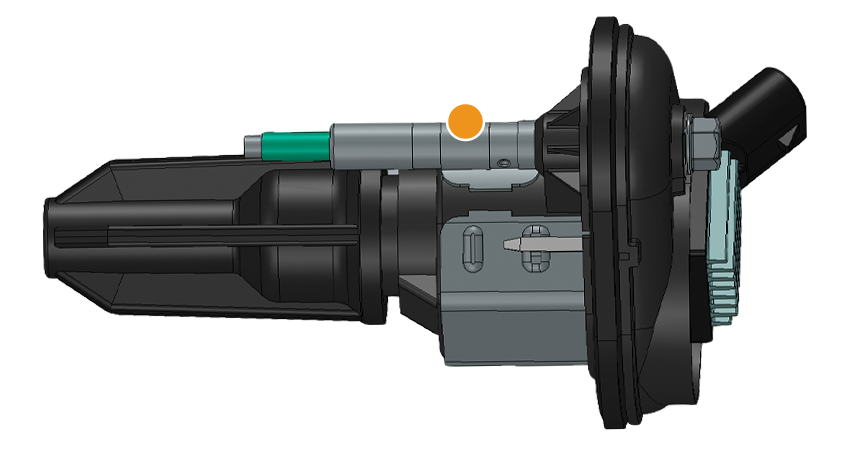

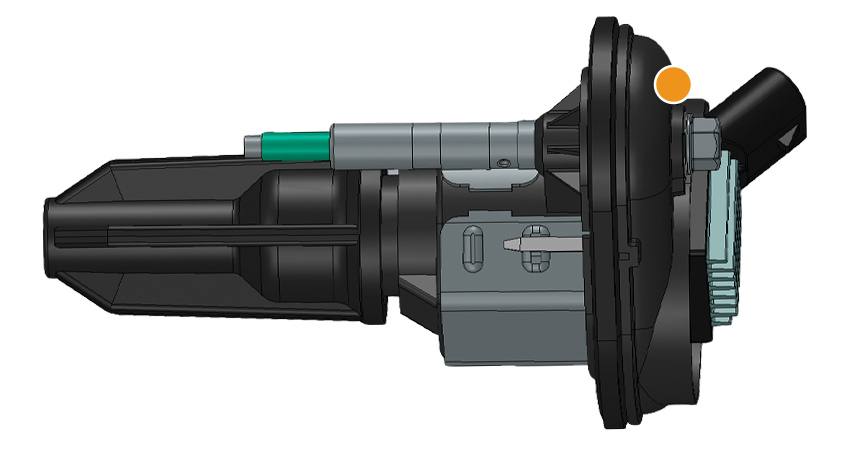

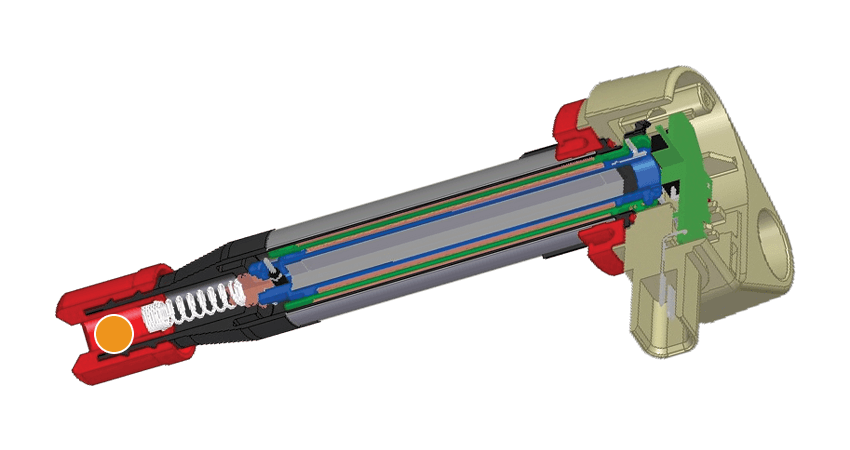

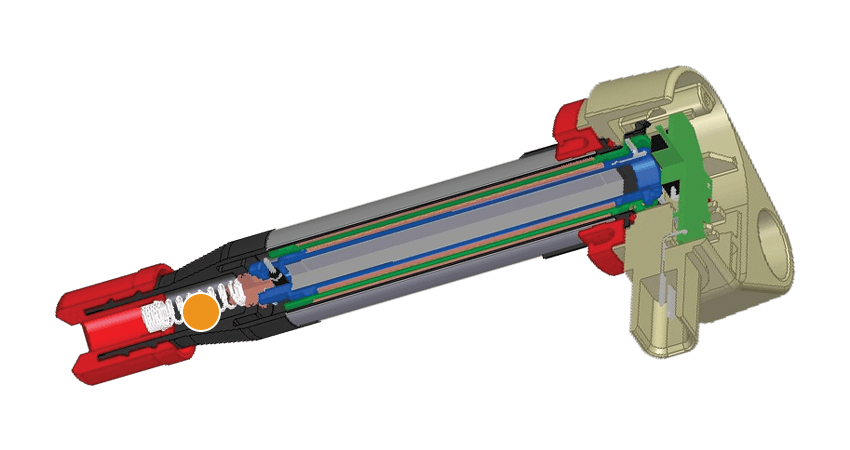

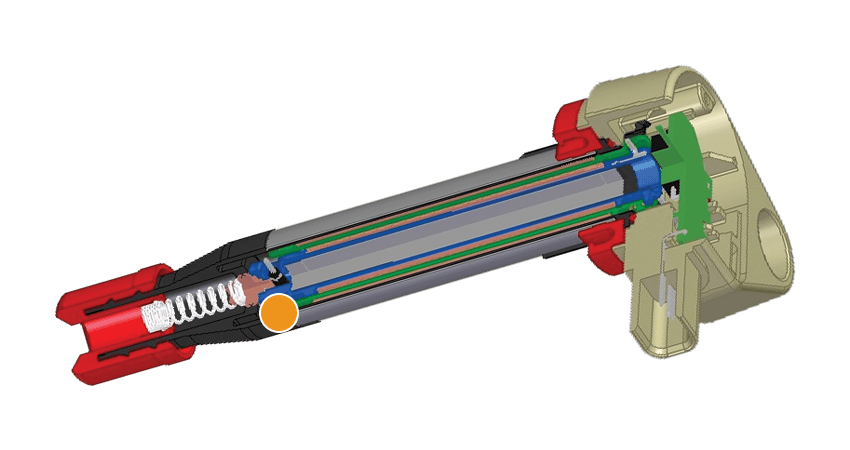

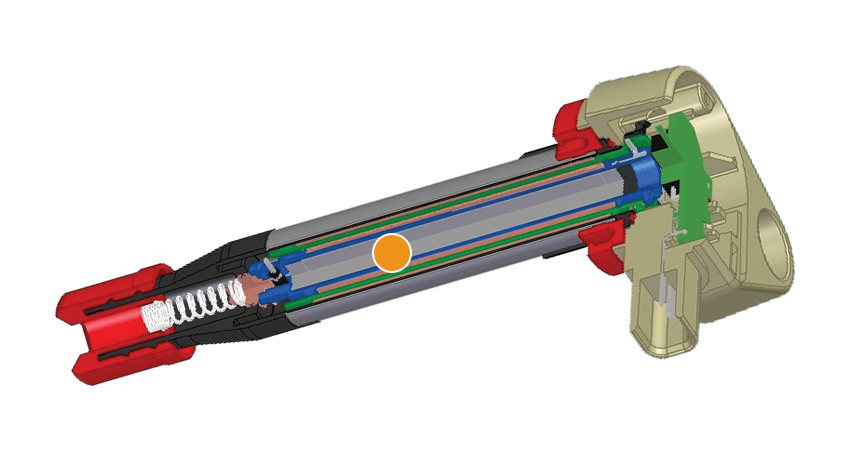

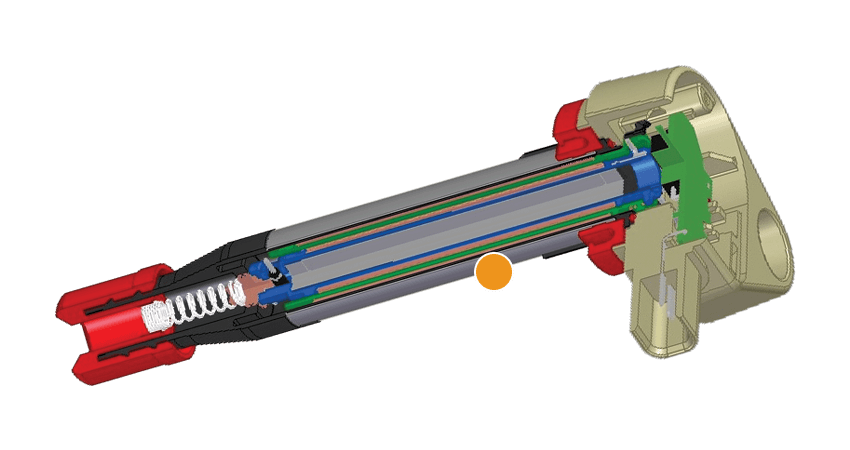

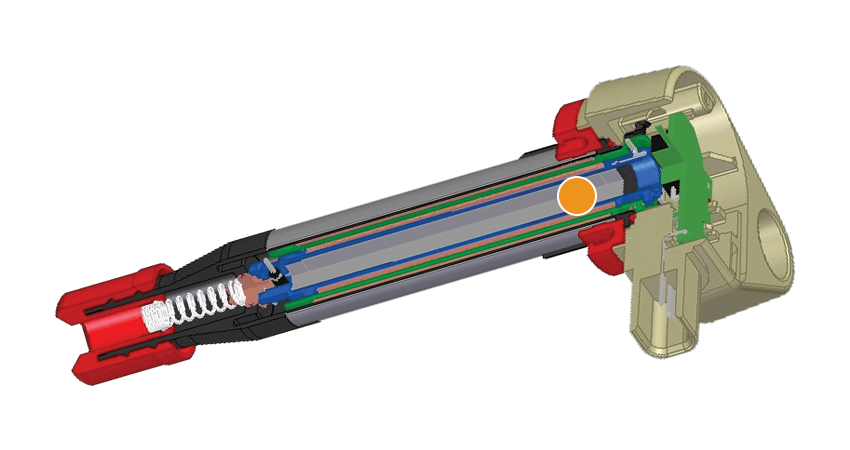

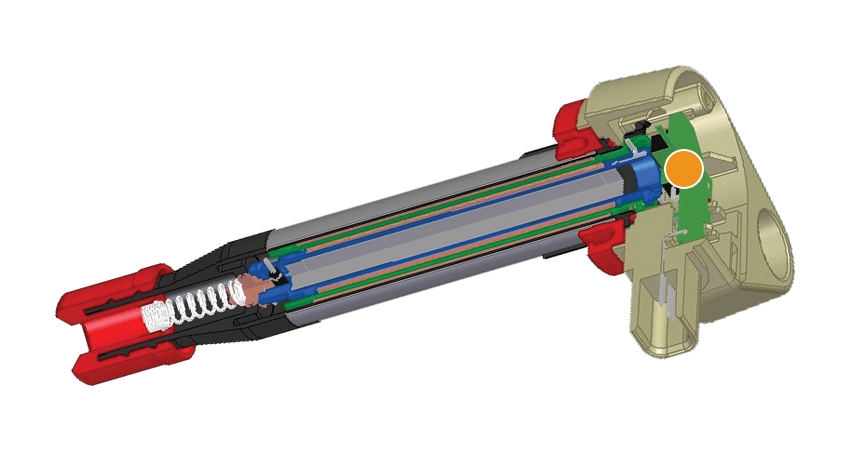

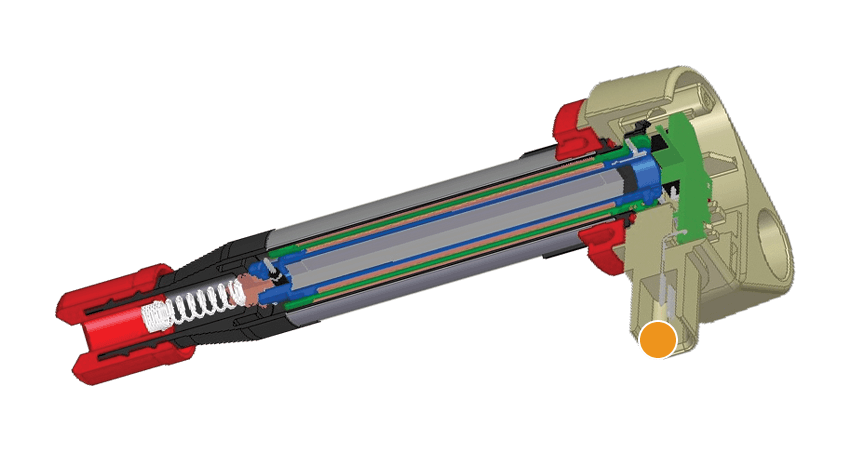

Advanced Pencil Coil Technology

As engine technology evolves, coil-on-plug technology will continue to play an increasingly important role. Standard® premium pencil coils are leading the way with exceptional coverage for this growing category. Let’s take a closer look at our UF242 pencil coil:

-

Silicone rubber boot withstands extreme heat and provides superior insulation.

-

Stainless-steel spring resists corrosion.

-

Primary and secondary bobbins made from fiberglass-reinforced polyethylene terephthalate prevent voltage flashover for extended service life.

-

Internal core made from grain-oriented electrical steel limits loss factor within magnetic circuit to reduce heat that may affect coil endurance.

-

External core made from oriented silicon steel for durability

-

Neodymium magnet produces max high-voltage output at all speeds.

-

Electronic ignition module profile and feedback signal matches fit, form and function of original.

-

Tin-plated brass terminals improve electrical contact and protect against corrosion.

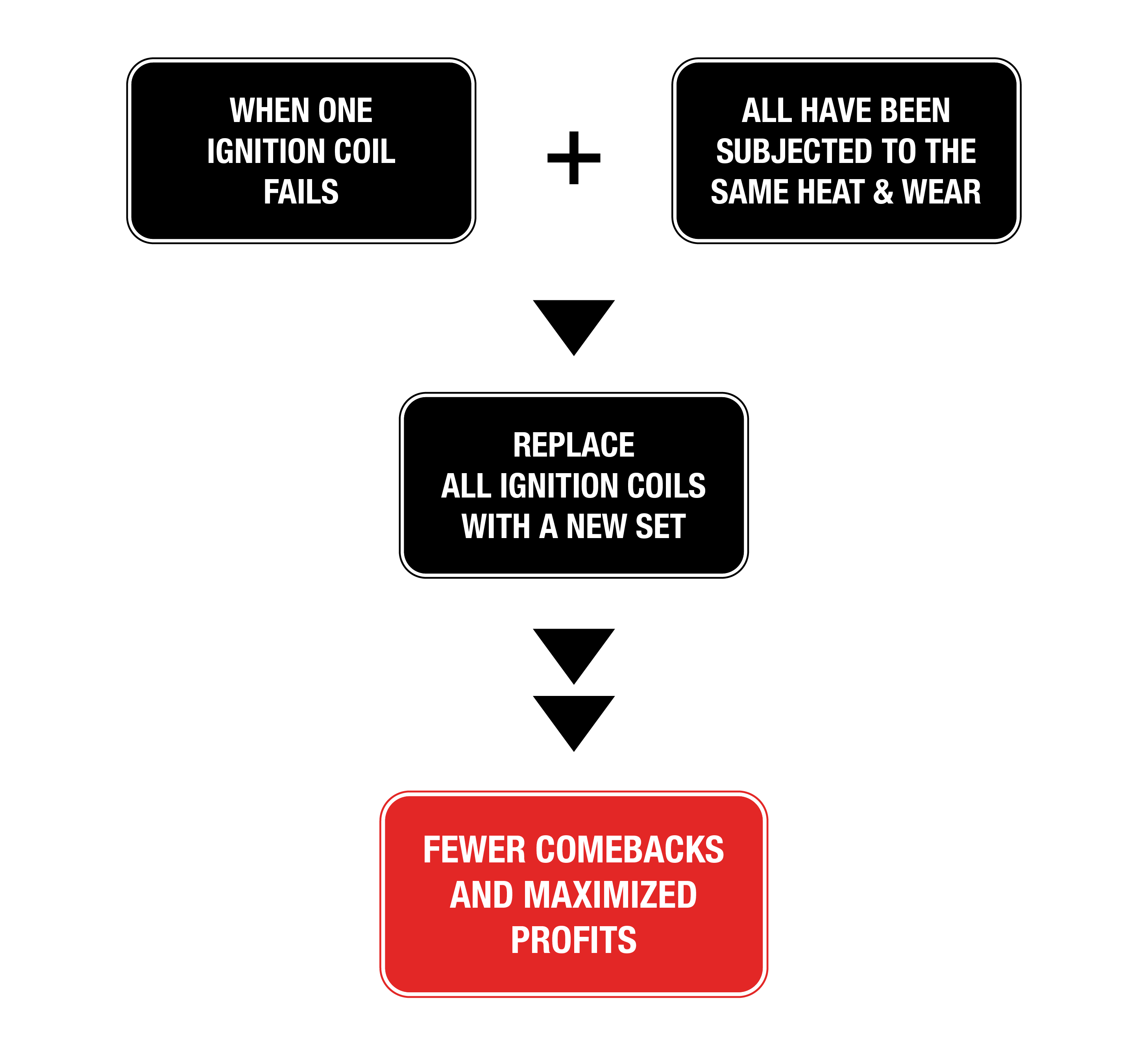

Tech Tip: Replace Ignition Coils in Sets

For more than 100 years, when the OE failed, technicians have trusted Standard® and Blue Streak® to deliver a part that’s equal to or better than the original it’s replacing.