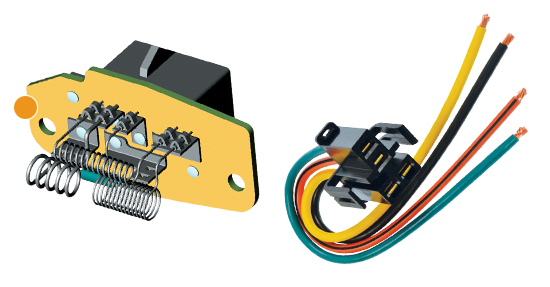

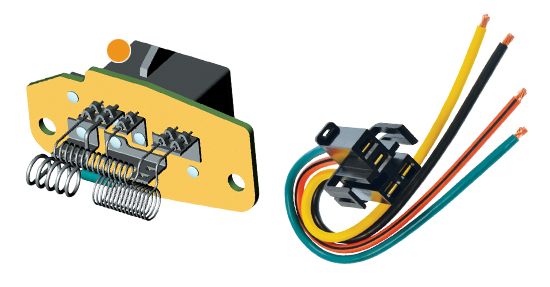

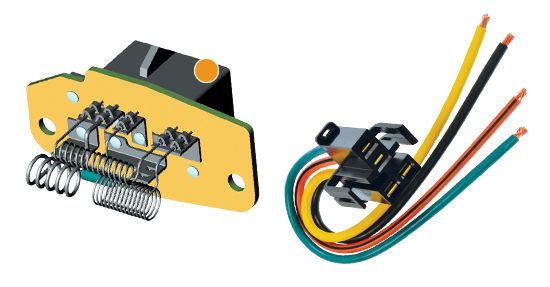

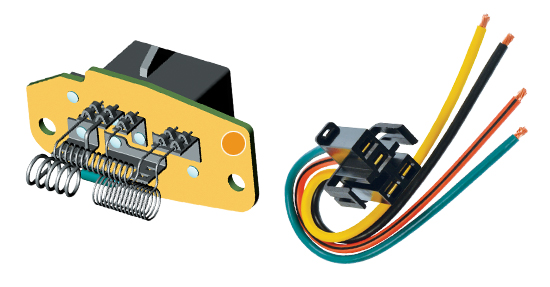

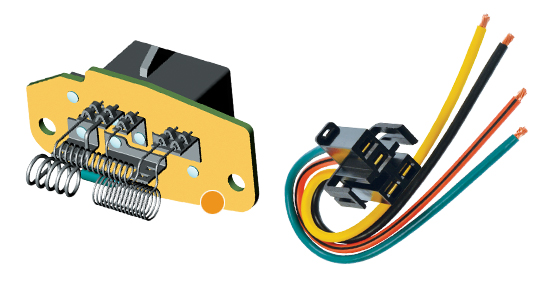

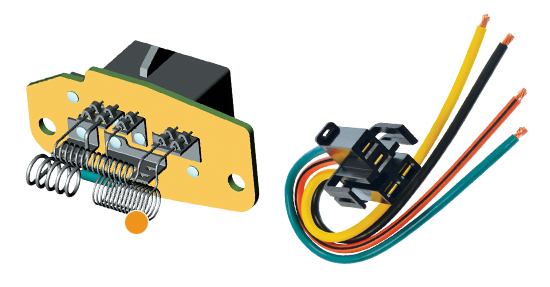

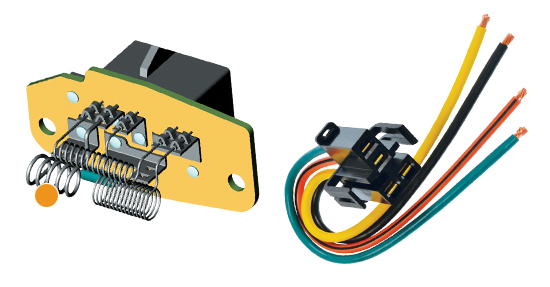

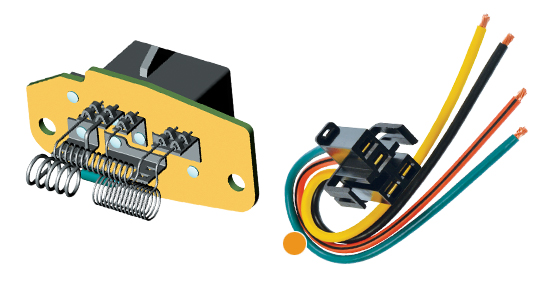

Blue Streak Blower Motor Resistor Kits

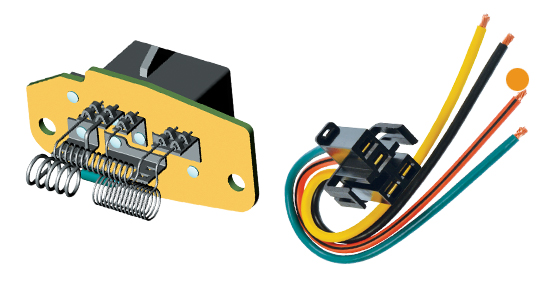

New BMR Kits Featuring our High-Temp Harnesses

Blue Streak® is proud to offer premium Blower Motor Resistor Kits as a high-quality solution for melted connectors and blower motor resistors. Blue Streak® improved on the OE design to create a connector that will withstand the excessive heat and reduce future failure.

Our connectors undergo thermal cycling testing to withstand extreme temperatures and prevent melting. Blue Streak® offers blower motor resistors that are direct-fit replacements and engineered to withstand the high amounts of current that can melt the resistor or connector.

-

Direct-fit replacement electrically operated resistor that replaces damaged OD units restoring A/C and heater blower motor variable speed control

-

Tin-plated steel terminals guarantee maximum contact and excellent fit, form and function

-

Made from high-quality ceramics with copper electrical connectors to ensure accurate and precise resistance values for long life and high performance

-

Thermally protected with on-board fuse

-

Our plants are IATF 16949 and ISO 9001-certified which ensures that every part is the right part for the right vehicle

-

Precision resistor coils for better fan control

-

Kanthal D resistor wire provides longer life span for higher-watt resistors

-

Undergoes testing with thermal cycling to withstand temperatures ranging from -22°F to 257°F

-

TXL copper wiring withstands high electric current to reduce heat-related failure

-

High-temp connector withstands extreme temperatures to prevent melting

What Do Blower Motor Resistors Do?

Blower Motor Resistors control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. The fan speed can be changed either by switching the blower resistor resistance mechanically, using a rotating lever, or electronically by the air conditioning system.

Blue Streak® Blower Motor Resistor Kits feature a problem-solving, high-temp harness.

We improved on the original, engineering a high-temp connector that withstands excessive heat and the extreme current that can melt an inferior resistor or connector.

What Are the Common Causes of Failure?

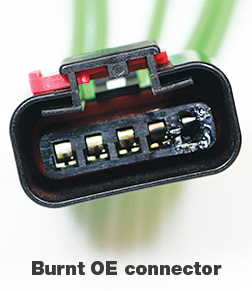

Blower motor resistors have high amounts of current running through their connectors due to technological advancements in today’s automotive heating and cooling systems. As a result, the current produces heat that can melt the connector and resistor. Worn OE blower motors can create a demand for current that also damages the resistor or module. The excess current melts the wiring and plastic shroud, damaging the interface pins on the controller’s circuit board.

Tech Tip

For repairs, use an inductive amp clamp to check that the blower motor current draw is less than 80% of the fuse rating on high. If the current is too high, replace the blower motor. Otherwise, the new resistor will fail too. You should also inspect the mating connector for signs of damage caused by excess heat.