- About Standard Sensors

-

Sensors

- Air Charge / Manifold Temperature Sensors

- Accelerator Pedal Sensors

- Anti-lock Brake (ABS) Sensors

- Brake Pad Wear Sensors

- Camshaft Sensors

- Crankshaft Sensors

- Coolant Temperature Sensors

- Exhaust Gas Temperature Sensor

- Knock Sensors

- MAP Sensors

- Mass Air Flow (MAF) Sensors

- Steering Angle Sensors

- Transmission Input/Output Sensors

- Vehicle Speed Sensors

- Yaw Rate Sensors

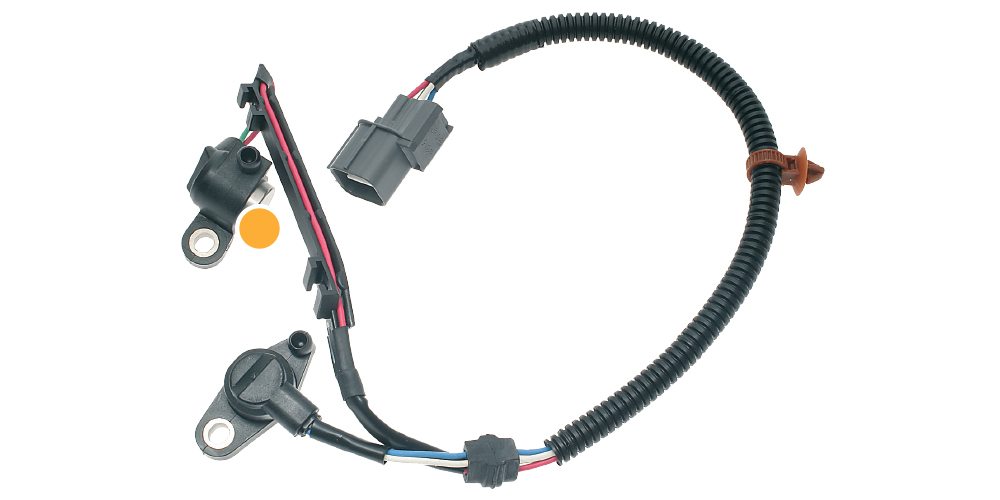

Crankshaft Sensors

The Coverage and Quality You Need

With hundreds of crankshaft sensors in our line, we supply comprehensive coverage for all makes, including Chrysler, Ford, GM, Honda, Mercedes-Benz, Nissan, Toyota, and Volkswagen. To ensure quality, we manufacture our crankshaft position sensors at our TS16949-certified facility in Reynosa, Mexico.

It’s this attention to detail that ensures every Standard® crank sensor meets or exceeds the original it’s replacing for performance and durability.

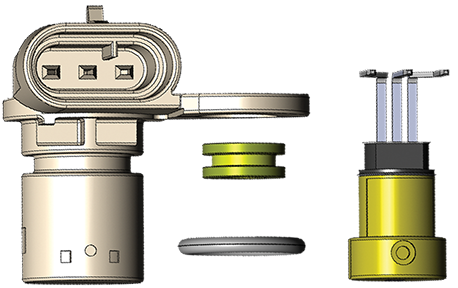

Designed with Premium Components

To ensure durability under extreme conditions, we subject each of our crank sensors to extensive end-of-line testing, including a 48- to 64-hour-long vibration test across three different planes. For a closer look at our crank sensors, including their premium components, watch the video above.

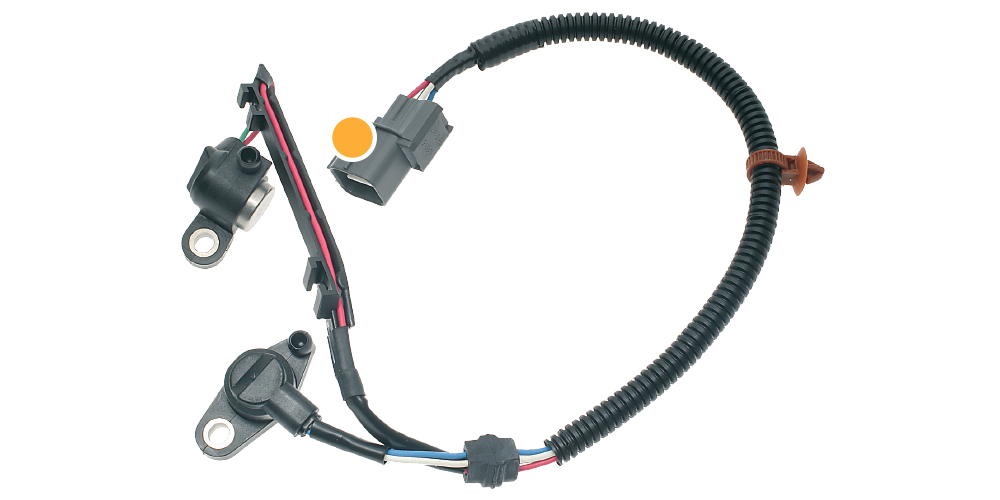

- Matching connectors and tin-plated brass terminals ensure accurate, watertight connection to harness

- Factory-installed grommets and wire clips ensure proper mounting during installation

- High-strength neodymium magnets ensure proper signal voltage to the ECM

- Protective sleeve prevents wires from chafing and creating short circuits

- Integrated A/D converter and digital signal processing with dynamically adaptive switch point improves accuracy and operation

Our Chamber Testing Cycles Between -40ºF to 257ºF

Our crankshaft position sensors undergo chamber testing that cycles from -40 degrees to 257 degrees Fahrenheit. We also subject each sensor to extensive end-of-line timing, pulse width, and signal amplitude testing.

What Our Testing Means for You

- Protect against over-voltage, under-voltage, reverse-voltage, and short circuits

- Maintain accuracy during heavy-duty shock, vibration, and maximum temperature conditions

About Crank Sensors

Located in the timing cover, or on side of the block with a cylindrical portion inserted in the block, crank sensors (a.k.a. crankshaft position sensors or crankshaft sensors) set ignition timing, supply the RPM signal, and determine engine speed. Crank sensors can fail due to excessive heat, faulty wiring harnesses, and sensor movement.

Tech Tip: Replace Cam/Crank Sensors Together

- With ever-increasing fuel economy regulations, modern engines are using VVT systems with multiple camshafts

- A typical DOHC engine will have 2-4 camshaft sensors as well as a crankshaft sensor

- If one sensor fails, it likely means that the other sensors are nearing the end of their service life, too

- To ensure proper performance, we recommend replacing the cam/crank sensors together

Honda Accord Crankshaft Sensor Replacement

Crankshaft Sensor

Located in either the timing cover or on the side of the block with a cylindrical portion that inserts into the block, crankshaft position sensors set ignition timing, supply the RPM signal, and determine engine speed.

-

Matching connectors and tin-plated brass terminals ensure accurate, watertight connection to harness

-

Factory-installed grommets and wire clips ensure proper mounting during installation

-

Protective sleeve prevents wires from chafing and creating short circuits

-

Integrated A/D converter and digital signal processing with dynamically adaptive switch point improves accuracy and operation

-

High-strength neodymium magnets ensure proper signal voltage to the ECM