Camshaft Sensor Kits Deliver The Complete Job

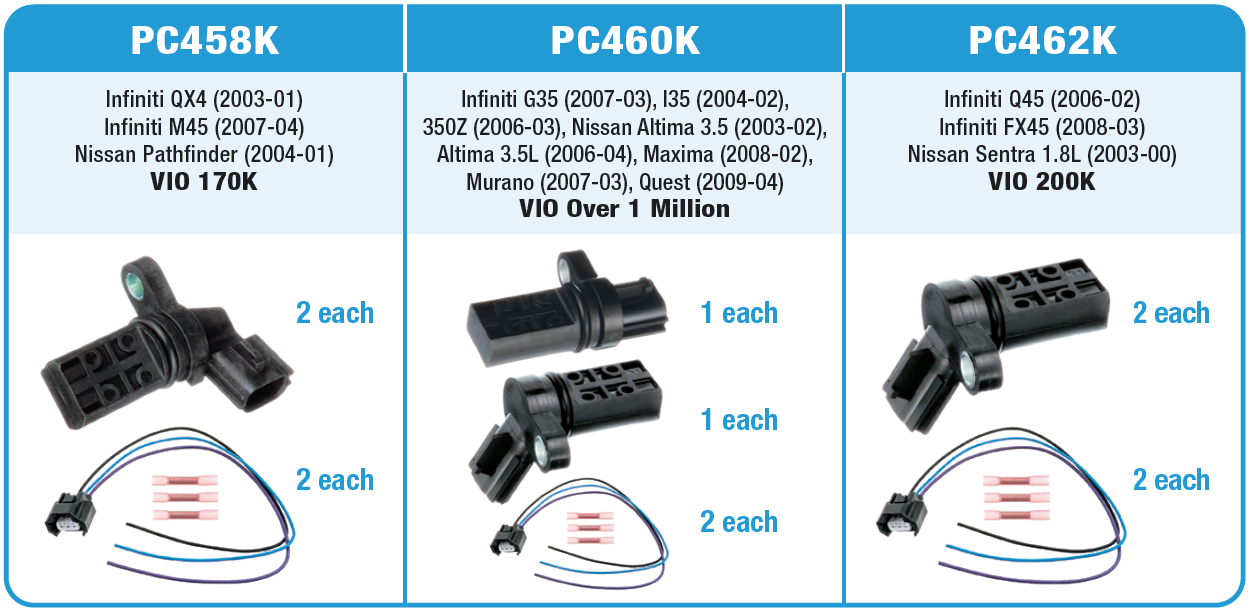

Standard Motor Products has unveiled its new line of Blue Streak® Camshaft Sensor Kits. That adds to its industry-leading product line of camshaft and crankshaft sensors, which includes more than 1,000 SKUs and 95 percent coverage. Each premium Blue Streak® kit contains two camshaft sensors along with the needed high-quality connectors to replace the melted/damaged originals.

Tech Tip: Replace Both Camshaft Sensors at the Same Time

Today’s engines use variable valve timing (VVT) systems with multiple camshafts and sensors to precisely monitor performance. A typical dual overhead camshaft (DOHC) engine will have 2-4 camshaft position sensors as well as a crankshaft position sensor.

If one cam sensor fails, it’s likely the others are nearing the end of their service life, too. We recommend replacing camshaft sensors together with high-quality Standard® sensors or Blue Streak® Camshaft Sensor Kits for a complete job and to reduce comebacks.

Basic, Expert Manufacturing

To ensure quality, we design and manufacture our Blue Streak® by Standard® camshaft sensors at our IATF 16949-certified facilities in Poland and Mexico. As a basic design center, we start with the finest components, while maintaining a strict adherence to engineering excellence and precision manufacturing.

To protect against failure, we manufacture camshaft sensors using premium components, including:

- Fluorocarbon rubber oil seal ensures secure fit

- Integrated waterproof connector ensures lasting performance

- Sealed construction withstands extreme under-hood conditions

- Advanced circuitry provides immunity from EMI (such as stray electro-magnetic fields, power spikes and static electricity) that meets ISO standards

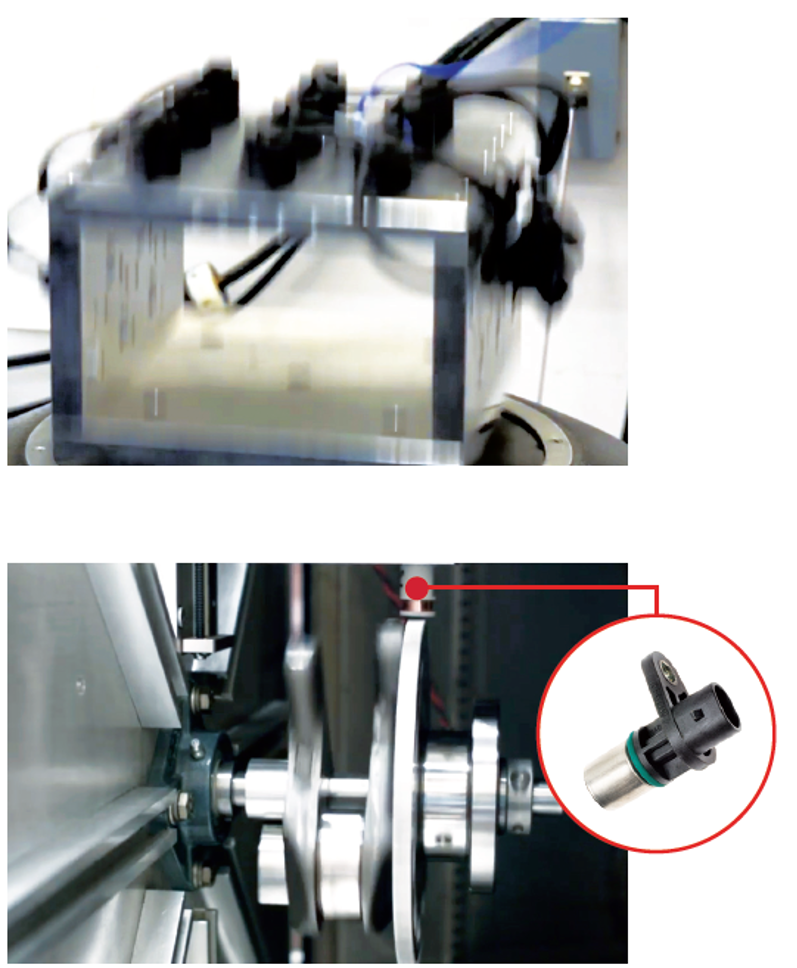

Extensive Testing

Blue Streak® puts each unit through end-of-line timing, pulse-width and signal-amplitude testing to make sure they perform and last. That means you’ll get a sensor that protects against over-voltage, under-voltage, reverse-voltage and short circuits, and that maintains accuracy during heavy-duty shock, vibration and maximum temperature conditions. Every sensor that leaves our facilities meets strict standards for quality, performance and durability.

48-HOUR VIBRATION TEST ENSURES DURABILITY

Sensors undergo three separate 48-64 hour vibration tests to confirm a long service life under the harshest conditions.

CHAMBER TESTING ENSURES PERFORMANCE

Chamber testing cycles from -40°F to 257°F to ensure optimal operation in extreme temperatures.

WHAT TESTING MEANS FOR YOU

Blue Streak® camshaft sensors protect against short circuits and voltage issues to perform under all operating conditions.

Backed by our

Limited Lifetime Warranty

We are so confident in the durability of our Blue Streak® by Standard® Camshaft components that we’ve backed every part with our Limited Lifetime Warranty.