- About Standard Sensors

-

Sensors

- Air Charge / Manifold Temperature Sensors

- Accelerator Pedal Sensors

- Anti-lock Brake (ABS) Sensors

- Brake Pad Wear Sensors

- Camshaft Sensors

- Crankshaft Sensors

- Coolant Temperature Sensors

- Exhaust Gas Temperature Sensor

- Knock Sensors

- MAP Sensors

- Mass Air Flow (MAF) Sensors

- Steering Angle Sensors

- Transmission Input/Output Sensors

- Vehicle Speed Sensors

- Yaw Rate Sensors

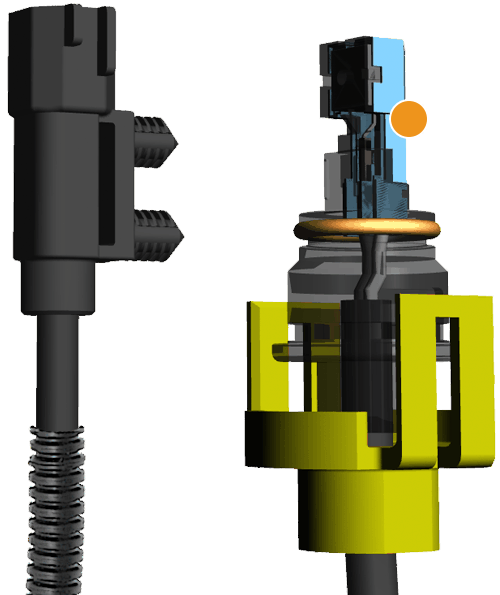

Anti-lock Brake (ABS) Sensors

The anti-lock braking system uses an ABS or wheel sensor to monitor the wheel speed and send this information to the ABS computer. The ABS computer uses this information to prevent the brakes from locking during a stop.

Standard ABS sensor line has complete coverage for domestic and import applications with over 2400 ABS numbers cataloged – and growing.

We include the quality and extras you need to ensure a proper install.

-

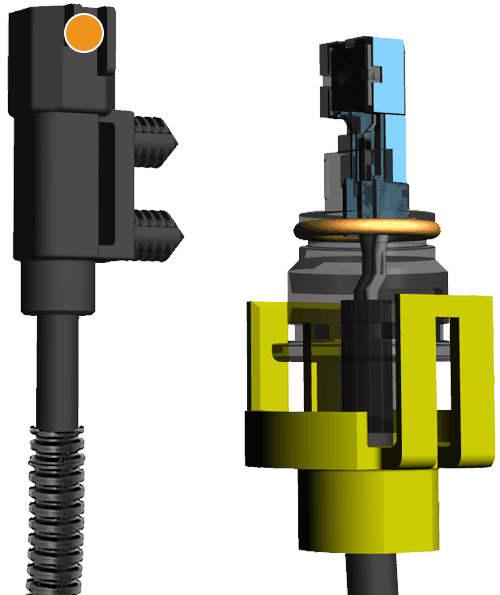

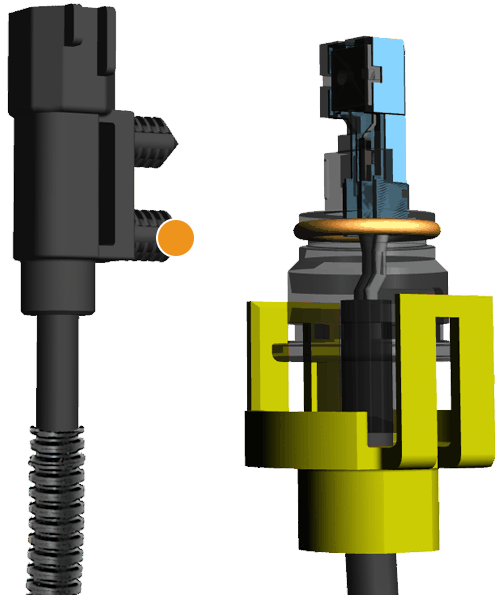

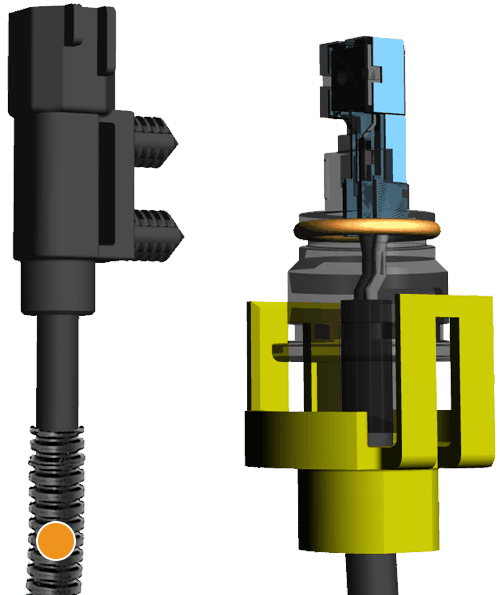

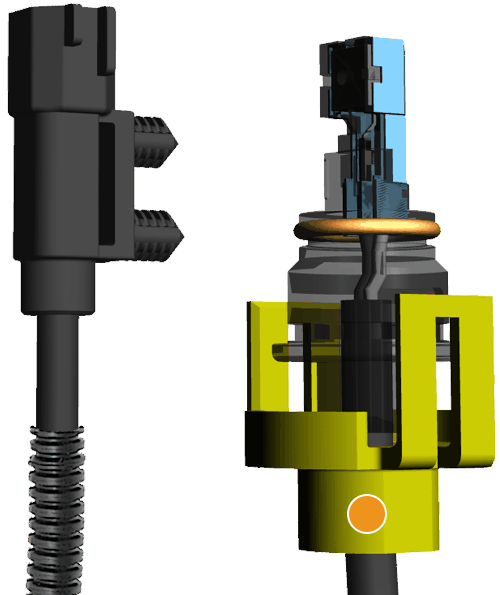

OE connectors and terminals are used to ensure accurate, water-tight connection to the engine wire harness

-

Grommets and wire clips are included on the harness to ensure proper mounting and routing within the car chassis

-

Wire harness comes with protective sleeve to prevent wires from chafing and creating short circuits

-

Sensors are 100% tested for proper functioning

-

Sensor housing is made from high quality glass reinforced plastic resin with both high temperature and environmental protection resistance

ABS Sensors - Fast Facts

- The ABS sensor is typically located in each wheel hub/rotor on a four channel ABS system. Some rear wheel drive applications have the sensor mounted in the rear differential

- Generally these sensors will fail as a result of clogging from metallic debris, brake dust or dirt due to exposure to the harsh elements

- A failing sensor can illuminate the MIL or ABS warning lamp, and may cause failure of the anti-lock braking system to operate safely and properly

- An ABS sensor can be visually inspected and the wire winding and sensor harness can be tested for opens, shorts and proper factory specified resistance with an ohm meter

ABS Sensor Testing

Rigorous Testing Means a More Reliable Sensor

Extensive laboratory and real-life testing includes evaluating the following:

- Shaft speed vs. delta voltage

- Output voltage and variation to OE

- Magnetic field strength and air gap

- Output wave form and pulse width

ABS Sensors Testing – See how the rest of the pack stacks up

We left no stone unturned; performing extensive laboratory and real life testing that included measuring and comparing shaft speed vs. delta voltage, output voltage and variation to OE, magnetic field strength, air gap, output wave form, pulse width as well as a complete physical product comparison to OE.

The Findings

Competition ABS Sensors

- No Consistency in signal output performance.

- Inferior materials in the magnetic circuit which results in low voltage output and can lead to ABS system failure.

- No Consistency in critical sensor dimensions which establish the gap between the sensor tip and target wheel which can lead to the sensor tip hitting the spinning target wheel causing sensor damage.

- Inadequate quality inspection and product testing.

- No Consistency in matching OE for form, fit and critical function.

How Does the Competition Measure Up?

The competition didn’t physically match up. It measured 29-51% lower voltage output when compared to the GM sample, leading to potential system failure. In the Ford test, the competition measured 45-74% lower voltage, with resistance and inductance flaws that result in poor performance.

Standard® ABS sensors delivered a more consistent signal output performance, matching OE for output voltage, resistance and all critical measurables.