- About Standard Sensors

-

Sensors

- Air Charge / Manifold Temperature Sensors

- Accelerator Pedal Sensors

- Anti-lock Brake (ABS) Sensors

- Brake Pad Wear Sensors

- Camshaft Sensors

- Crankshaft Sensors

- Coolant Temperature Sensors

- Exhaust Gas Temperature Sensor

- Knock Sensors

- MAP Sensors

- Mass Air Flow (MAF) Sensors

- Steering Angle Sensors

- Transmission Input/Output Sensors

- Vehicle Speed Sensors

- Yaw Rate Sensors

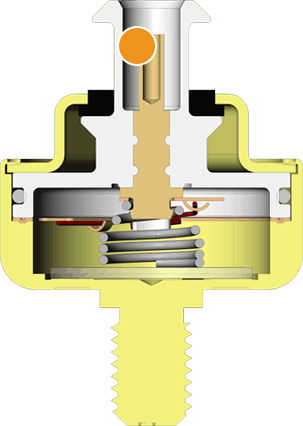

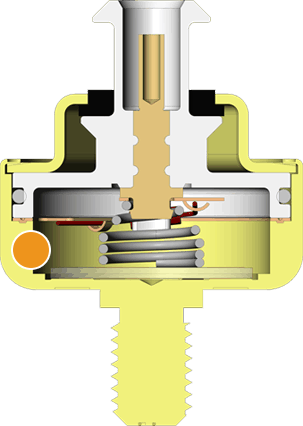

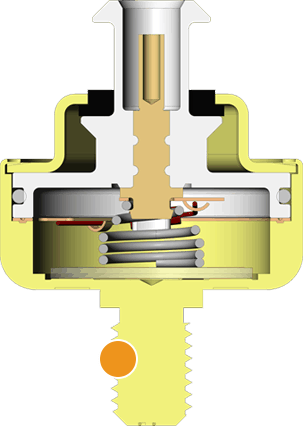

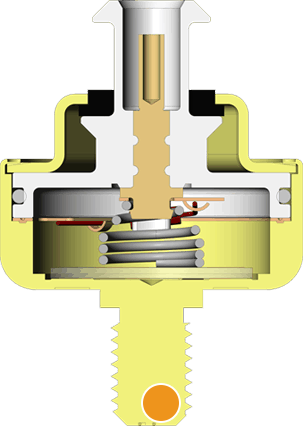

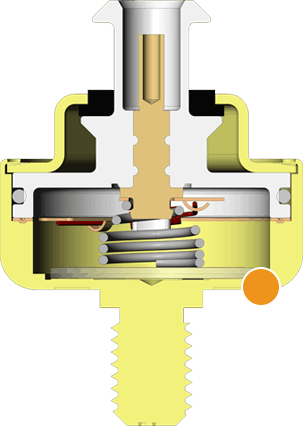

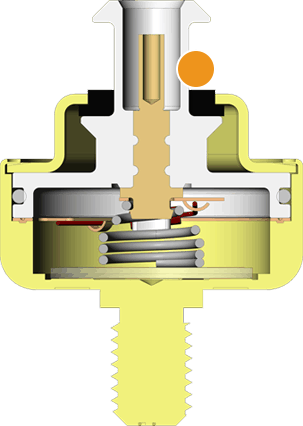

Knock Sensors

Knock sensors create a voltage signal based on the vibrations caused by detonation. The computer uses this signal to retard timing when spark knock occurs.

-

An automated data acquisition system continuously monitors sensor output to ensure it responds with appropriate voltage at the specified frequency rate

-

The Sensor body is precision machined to tune the resonant frequency to the engine knock frequency

-

All units are 100% tested using an accelerometer vibration test to ensure trouble-free operation

-

Designed to respond to knock frequencies up to 1000Hz and shifts in engine knock frequency, making it more effective over a broad range of vehicle conditions

-

The Piezoelectric disc is the heart of the sensor. It is a sintered ferroelectric ceramic disc precision ground to tight physical tolerance

-

Primary thermistor wire leads resistance welded to connector terminals to ensure a reliable electrical connection in an environment of high vibration and changing temperature