-

What's In Your Box

- History, Trusted Brands & Training

- Manufacturing, Engineering & Testing

- Parts are Just Parts?

- ABS Speed Sensors

- ADAS

- Blower Motor Resistors

- Blue Streak Import Coils

- Blue Streak Kits

- Camshaft & Crankshaft Sensors

- Collision Repair Program

- Electronic Throttle Bodies

- EV / Hybrid Program

- EVAP Components

- Gas Fuel Injection

- GDI Injection

- Ignition Coils

- Oil Filter Housing Kits

- Oil Pressure Switches

- Parking Brake Actuators

- TPMS

- Turbocharger Kits

- Variable Valve Timing

- Resources

- More than 1000 SKUs and 95% coverage for domestic and import applications

- We manufacture top-quality cam/crank sensors in our IATF 16949-certified facilities

- All cam and crank sensors undergo extensive vibration and chamber testing to ensure durability

We engineer and manufacture the highest quality and most precise camshaft and crankshaft position sensors.

Camshaft and crankshaft sensors are designed and manufactured at our advanced Poland and North American IATF 16949-certified facilities. Our expert design centers start with the finest components, while maintaining a strict adherence to engineering excellence and precision manufacturing.

It’s this attention to detail that ensures every Standard® cam and crank sensor meets or exceeds the original it’s replacing for performance and durability.

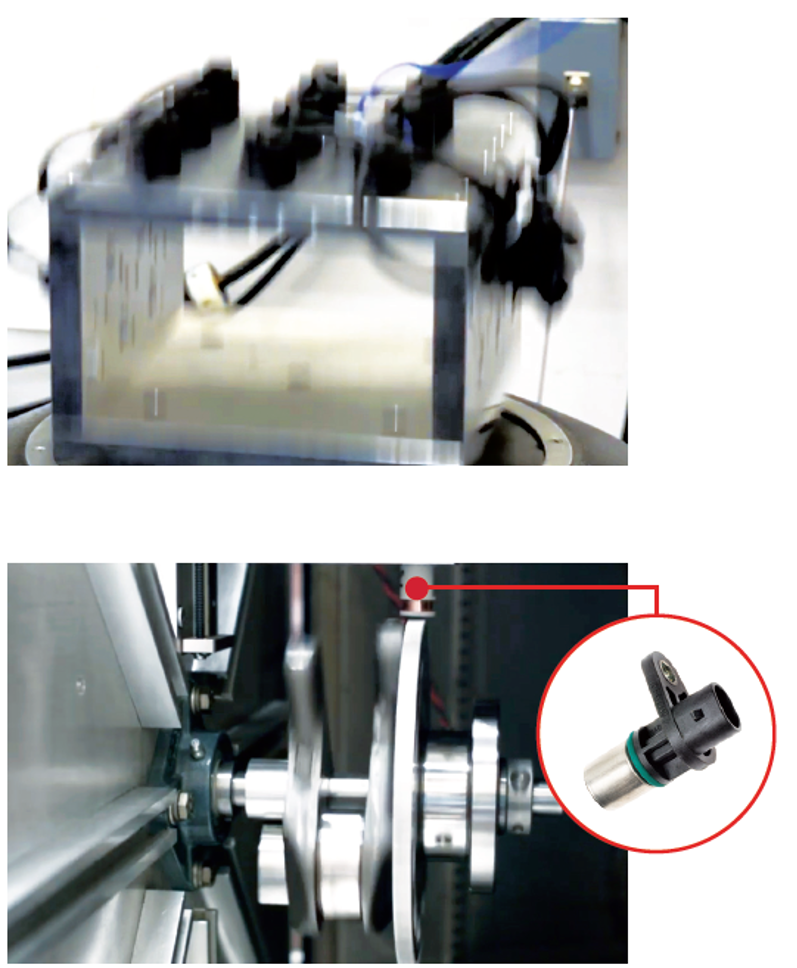

Cam/Crank Sensor Testing

48-Hour Vibration Test Ensures Durability

Sensors undergo three separate 48-64 hour vibration tests to ensure a long service life under the harshest conditions.

Chamber Testing Simulates Extreme Temperatures

To ensure optimal operation, chamber testing cycles from -40°F to 257°F. We also run extensive end-of-line timing, pulse width and signal-amplitude testing.

What Our Testing Means For You

Standard® Cam and Crank Sensors provide complete protection to deliver precise performance and durability under all operating conditions.

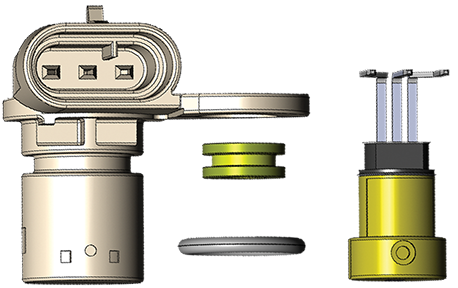

We Start with Premium Components

Our commitment is to use only the finest components to produce camshaft and crankshaft sensors that perform under the toughest conditions.

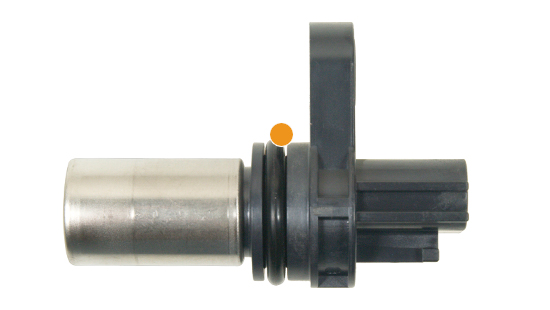

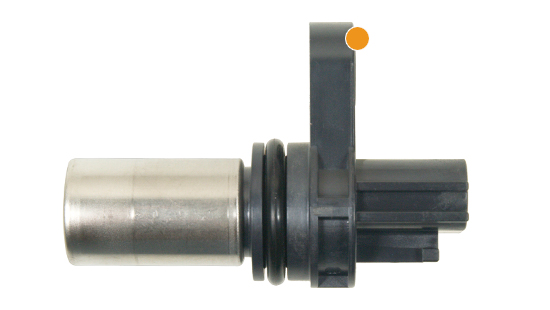

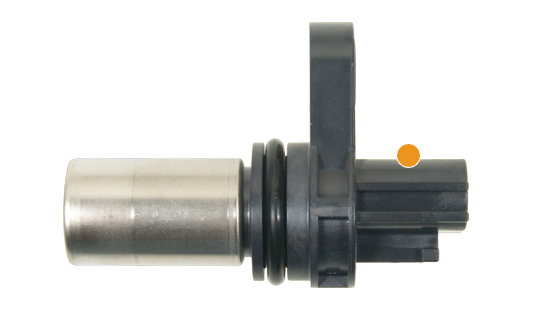

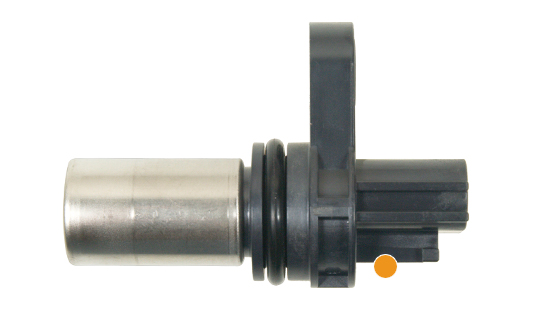

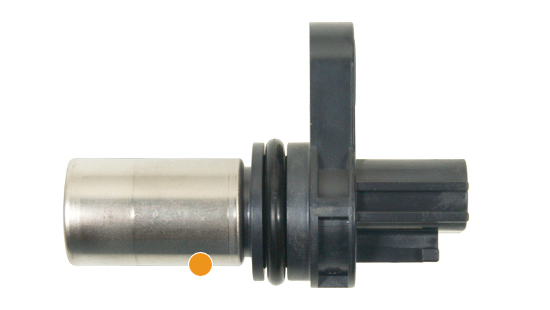

Premium Camshaft Position Sensors

-

Sealed metal casing prevents oil intrusion.

-

Fluorocarbon rubber oil seal ensures secure fit.

-

Rotated mounting ear matches latest OE-design.

-

Sealed construction withstands extreme under-hood conditions.

-

Integrated waterproof connector ensures lasting performance.

-

Advanced circuitry provides immunity from EMI (such as stray electro-magnetic fields, power spikes and static electricity) that meets ISO standards.

Blue Streak Camshaft Sensor Kits

Blue Streak® Camshaft Sensor Kits include premium Camshaft Sensors along with needed connectors to replace worn or damaged originals.

Blue Streak® developed high-quality Camshaft Sensor Kits to provide technicians with what they need to do the complete job. Blue Streak® Kits contain premium camshaft sensors and the needed connectors. Our enhanced Kits include two Blue Streak® Camshaft Sensors along with the high-quality connectors to replace the melted or damaged originals.

View our Blue Streak Just the Facts: Camshaft Sensor Kits flyer

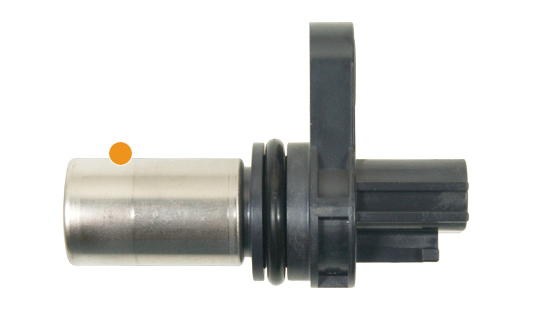

Superior Crankshaft Position Sensors

-

Matching connectors and tin-plated brass terminals ensure accurate, watertight connection to harness.

-

High-strength neodymium magnets ensure proper signal voltage to the ECM.

-

Factory-installed grommets and wire clips ensure proper mounting during installation.

-

Protective sleeve prevents wires from chafing and creating short circuits.

-

Integrated A/D converter and digital signal processing with dynamically adaptive switch point improves accuracy and operation.

Blue Streak Crankshaft Sensor Kits

Blue Streak® Crankshaft Kits include a high-quality Crankshaft Sensor and a direct-replacement connector for a complete repair solution.

Kits include a high-quality Crankshaft Sensor and a direct-replacement connector for a complete repair solution. We developed high-quality Crankshaft Sensor Kits to provide technicians with what they need to complete the job. Kits contain premium Crankshaft Sensors with a high-quality electrical connector to replace the melted or damaged originals—everything a technician needs to perform the repair. We offer over 20 Crankshaft Sensor Kits, with more coming in 2023.

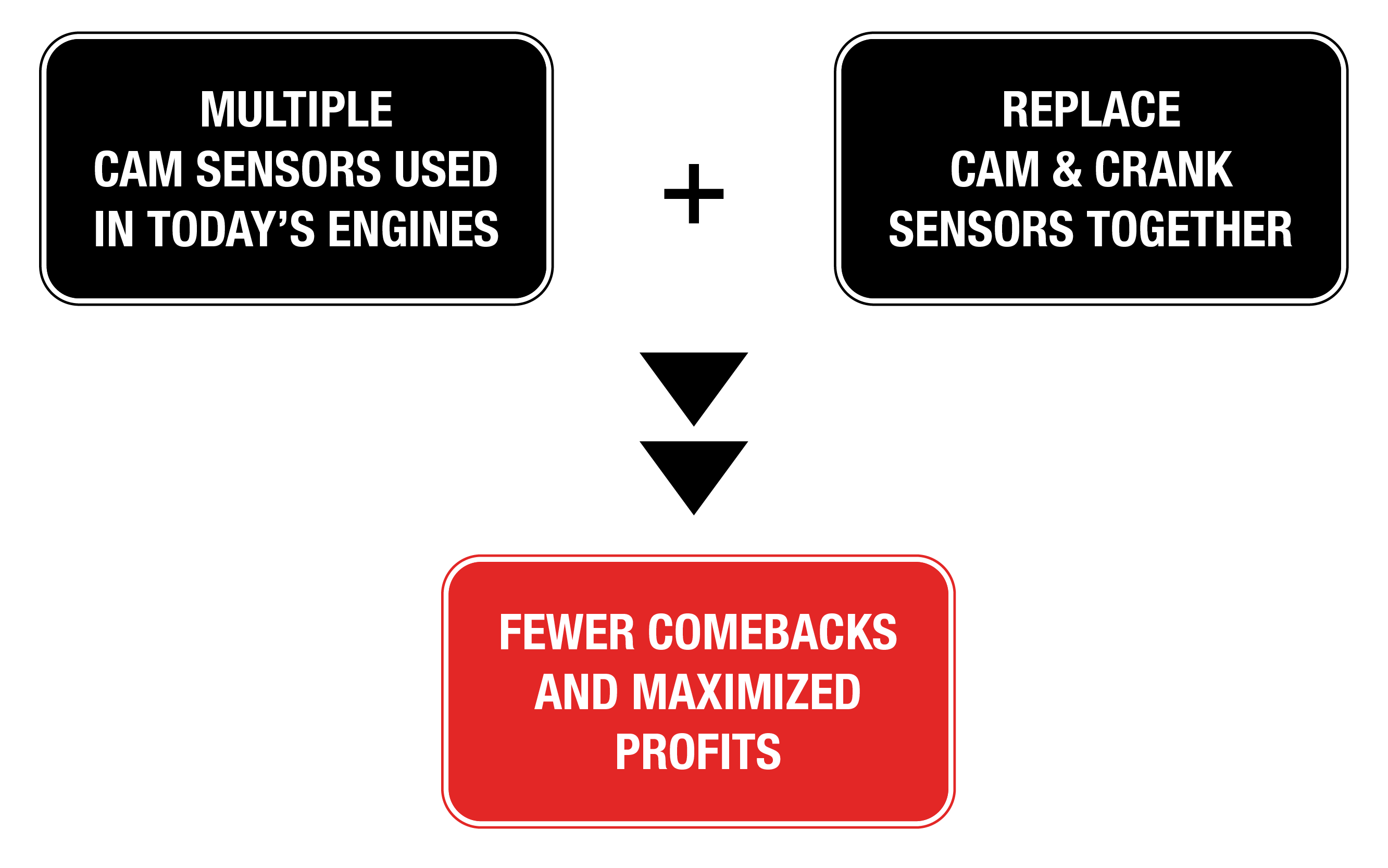

Tech Tip: Replace Camshaft and Crankshaft Position Sensors Together

Today’s engines use VVT systems with multiple camshafts and sensors to precisely monitor performance. A typical DOHC engine has 2-4 camshaft position sensors as well as a crankshaft position sensor.

For more than 100 years, when the OE failed, technicians have trusted Standard® and Blue Streak® to deliver a part that’s equal to or better than the original it’s replacing.