Diesel Fuel Injector Kits

Providing Solutions to Well-Known Problems

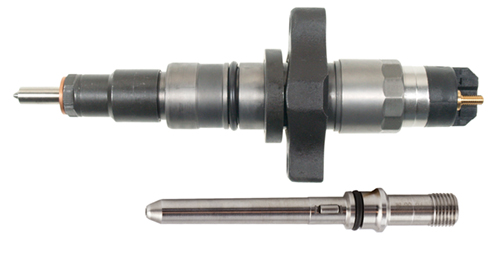

(Image: Standard FJ933K)

Unlike the high-pressure fuel pump, fuel lines, and fuel rail, once installed, fuel feed tubes are no longer visible to technicians. In the event that one or more of the tubes does not seal properly because of wear, the general thought is that the injector is not functioning properly.

The real issue is that fuel is leaking back to the fuel return line from the tube itself. Failure to replace each fuel feed tube when replacing fuel injectors is a common mistake that leads to product failure. Replacing the fuel feed tube every time an injector is replaced allows for a proper installation. This practice also helps the technician save time and money as comebacks, warranties and misdiagnosed Injector problems are avoided.

The new Diesel Fuel Injector Kit includes a remanufactured injector, fuel feed tube, and installation instructions and tips, all backed by professional training support.

Known for its extensive line of diesel products, especially its new and remanufactured fuel injectors and components, Standard® has unveiled a new line of Diesel Fuel Injector Kits. The new Diesel Fuel Injector Kits include a remanufactured injector, fuel feed tube, and installation instructions and tips, all backed by professional training support.

The initial offering from Standard® provides coverage for more than 650,000 vehicles-in-operation (VIO) in North America.

Basic Manufacturing

Manufactured at Standard Motor Products’ ISO 9001:2015-certified plant in Greenville, SC, each Diesel Fuel Injector Kit includes a remanufactured fuel injector. To ensure that each remanufactured diesel injector performs flawlessly, engineers first ensure the injector remains contamination-free during the rebuild process. They replace every necessary component with a new one and administer a precise, repeatable process that is followed every time.

Remanufactured fuel injectors included in the Diesel Fuel Injector Kits feature:

- New core components such as O-rings, springs, nozzles, delivery valves, shims, gaskets and solenoids

- Extensive testing against OEM product, including shot-to-shot, fuel delivery and response time tests at different pulse widths, pressure levels and RPMs

- Critical tolerances of components are measured, visually inspected and electrical tested, and either replaced or reconditioned as needed

- Reassembled using precision tooling in temperature and humidity-controlled room with fixturing on all stations

Common Failure Modes

Contamination in the fuel supply continues to be one of the most common reasons for both premature failure of components as well as the original reason for the initial failure. And once contaminants make their way to the high-pressure fuel pump, fuel feed tubes or injectors, a failure is all but eminent.

Also, installing the incorrect part number for 2004 model year vehicles is an ongoing issue. There are two unique fuel injectors used. Although the fuel injectors appear to physically be the same, they are not interchangeable. One application is designed with an 8-port injector nozzle, while the other utilizes a 5-port injector nozzle.

Aftersales Support and Training

Each Diesel Fuel Injector Kit includes Standard® Motor Products’ Diesel in the Box Install Package. The in-the-box technical support program helps eliminate warranty returns due to faulty inspections and includes the following:

- Technician ‘Must Do’ card

- Step-by-step, color, installation instructions

- ‘Call Before You Install’ toll-free hotline

- All the components for the complete repair

By testing the fuel before making a repair, technicians can reduce the chances of a comeback by testing and identifying the four most common contaminants found in fuel systems today.