Blue Streak Import Ignition Coils

Manufactured at our most advanced manufacturing facility in Poland, the Blue Streak® Import Ignition Coil line provides customers and technicians with the features and competitive benefits that come from the superior design, engineering and testing that Blue Streak® is known for.

Product of Superior Design

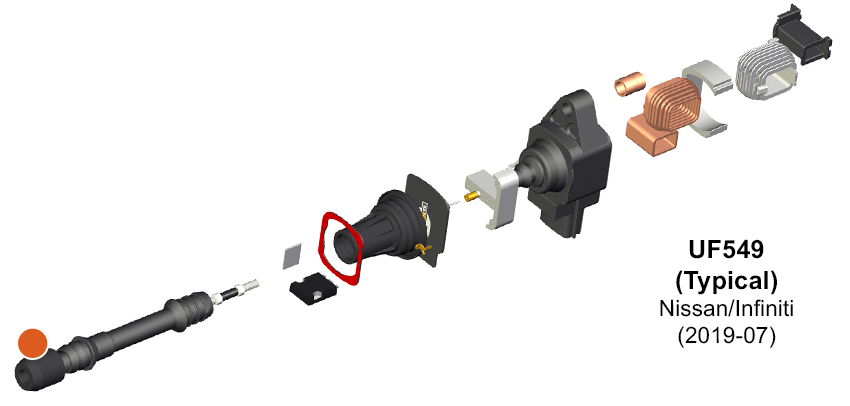

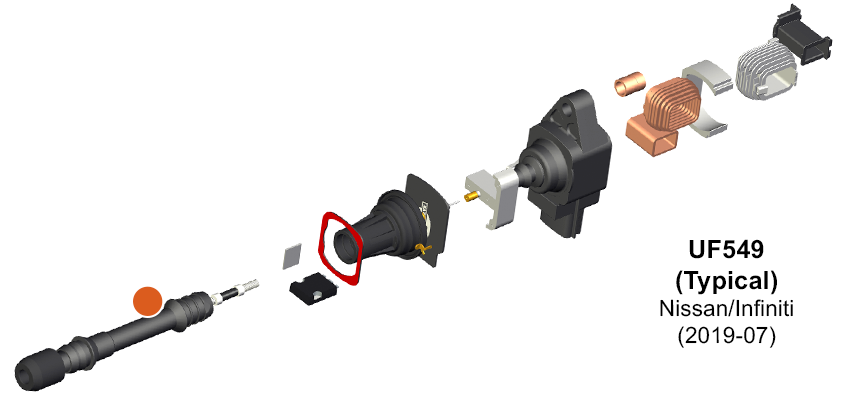

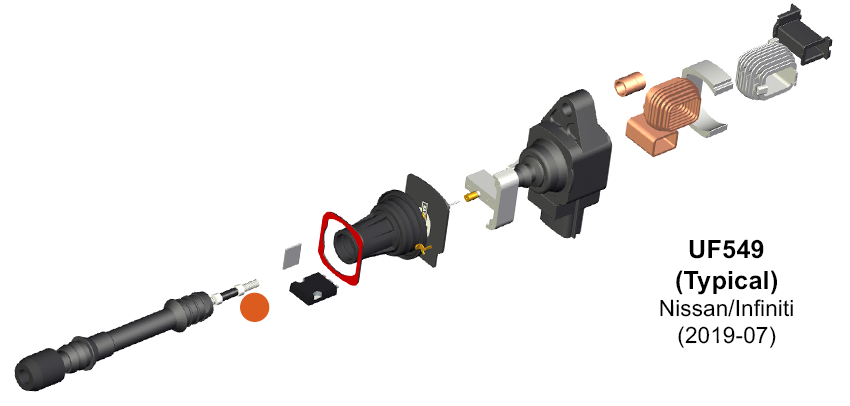

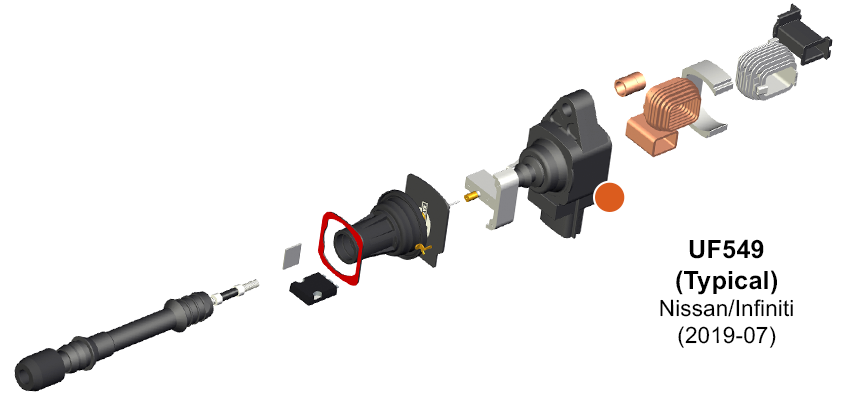

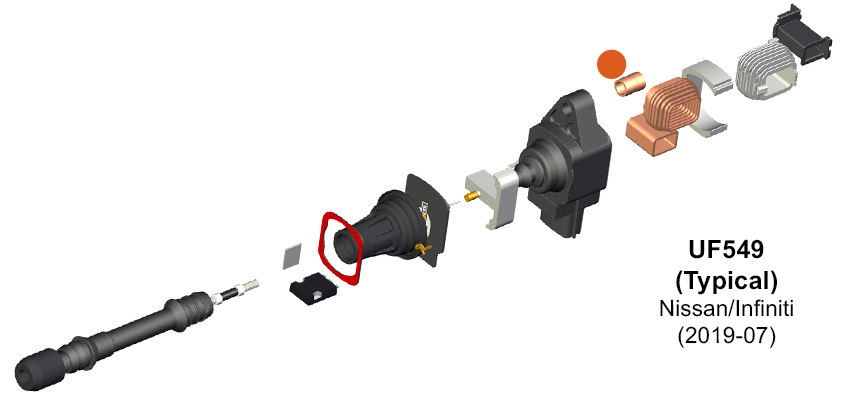

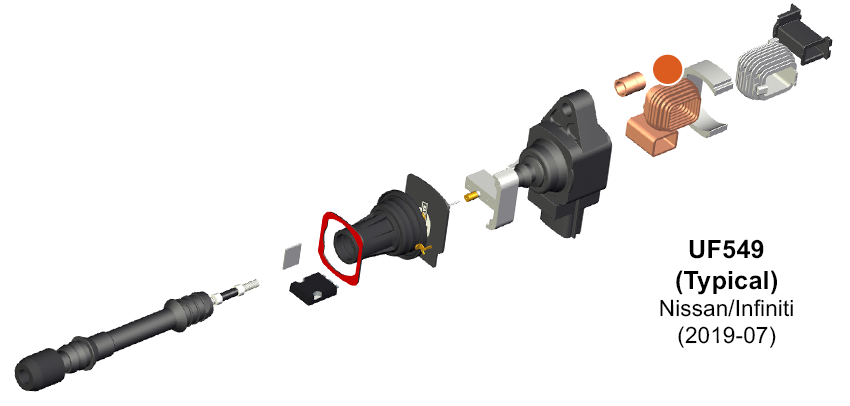

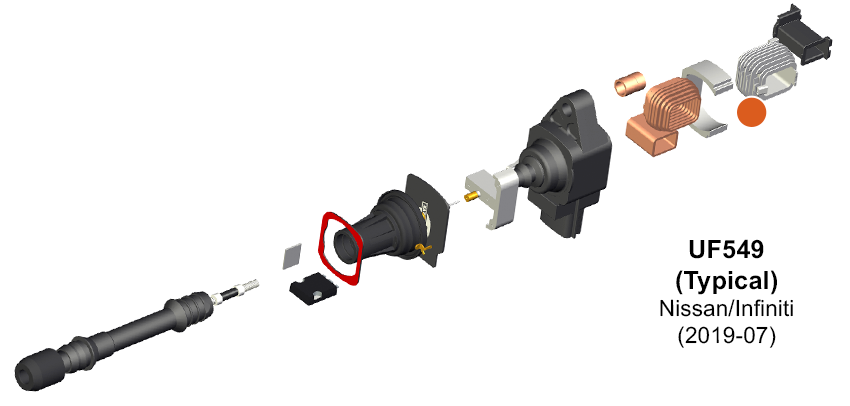

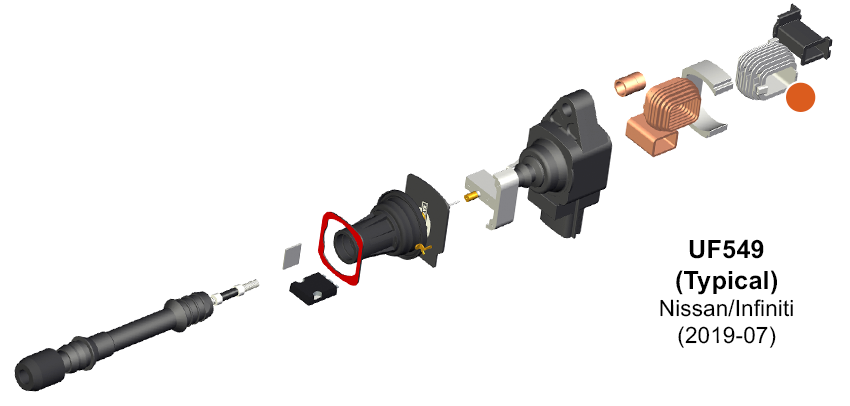

Blue Streak’s import ignition coils are the product of superior design, manufacturing and testing. For example, take our UF-549, one of the many new import ignition coils in our line.

-

Flexible high-temp silicone boot withstands extreme heat for superior insulation

-

One-piece hi-dielectric strength housing withstands heat stress and secondary arcing for improved durability

-

Stainless steel spring resists corrosion

-

High-dielectric epoxy injected into case in vacuum to eliminate air pockets and prevent moisture intrusion

-

Upgraded brass mounting bushing outperforms the OE and competitors in salt spray environmental testing

-

Precision-wound 100% ETP copper secondary windings provide higher resistance to shorts and dielectric breakdown

-

Additional segmented bobbin sections prevent internal arcing and high-voltage breakdown

-

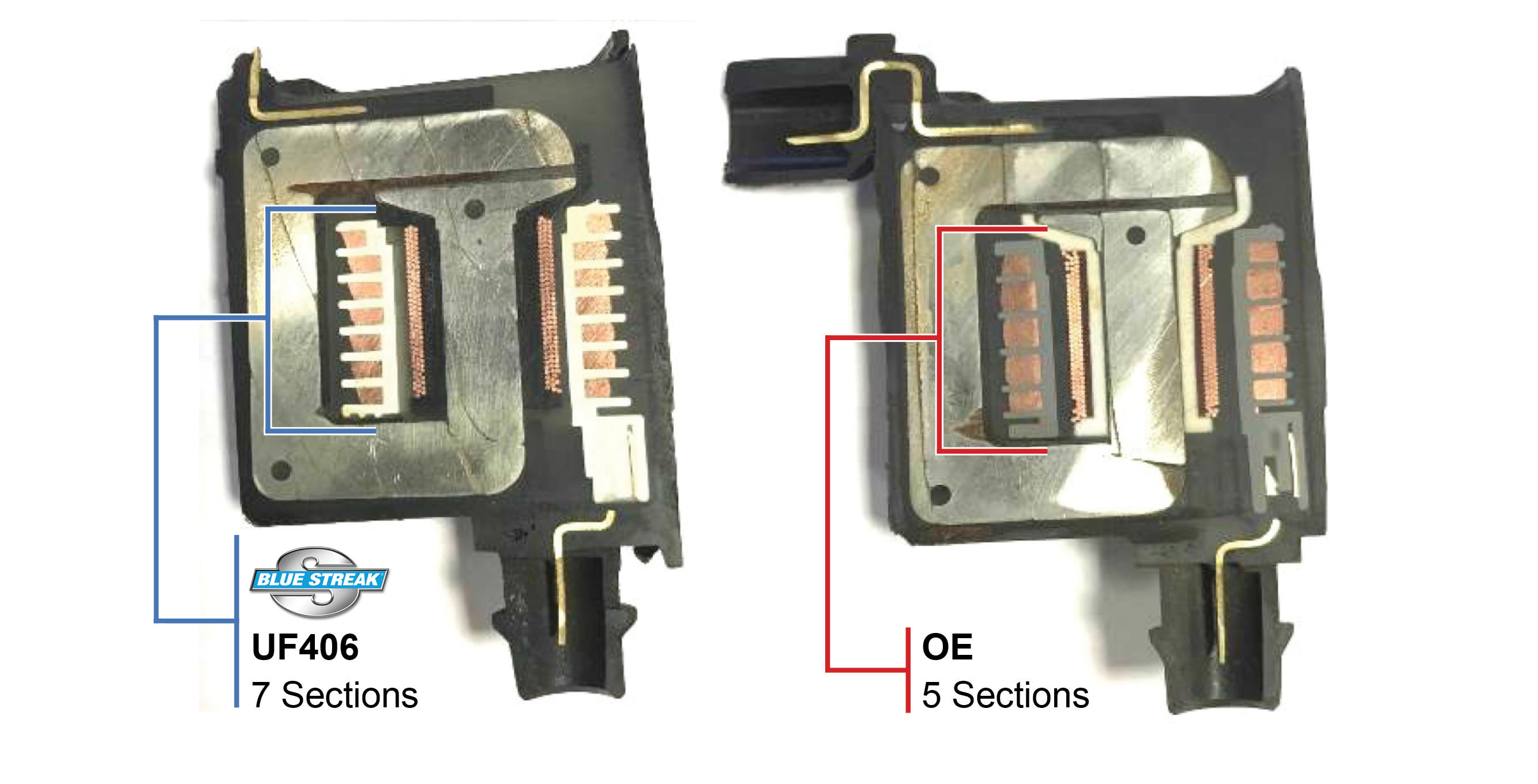

More secondary bobbin sections compared to the OE coil

Simplified Core Separator

Simplified core separators extend the durability of the coil by compensating for thermal expansion.

Blue Streak’s precision-wound bobbin features more sections and simplified core separators to produce higher secondary voltage when required for better coil performance and longer service life. Our engineers conducted voltage tests featuring our Blue Streak® premium import ignition coil, the OE coil and two competitor coils.

See how our UF-549 stacked up in the results below.

Source: SMP Poland Testing Lab, 2020-2021

Upgraded Brass Bushing

Our SMP Poland engineers subjected our UF-549, an OE coil and the coils of three competitors to a 200-hour salt spray test. The results speak for themselves. The Blue Streak® coil with an upgraded brass bushing outperformed the OE and competitors in the salt spray environmental test with the least amount of corrosion and rust.

Source: SMP Poland Testing Lab, 2020-2021

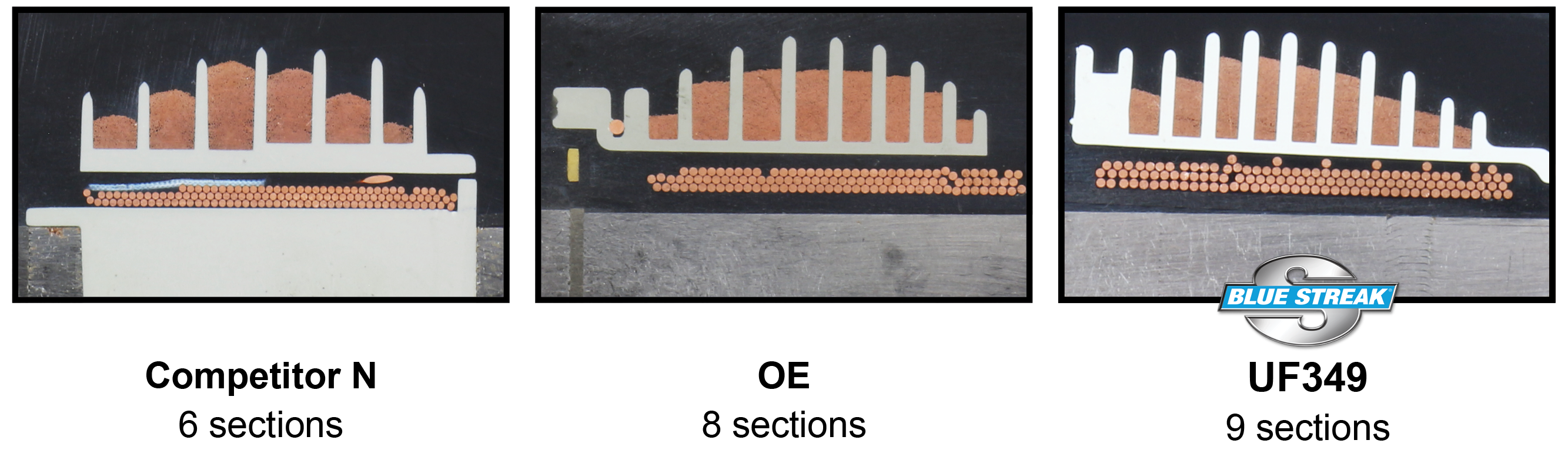

Case Study: Blue Streak® Ignition Coil (UF-349)

Case Study: A typical system can produce up to 30 kV as needed.

- Competitor N features 6 sections and is pushing 5 kV per section.

- The OE features 8 sections and pushes 3.75 kV per section.

- Blue Streak® with 9 sections only pushes 3.33 kV per section.

Results: Blue Streak® coils have more secondary bobbin sections than both the OE and Competitor N. More sections means less heat and longer coil life.

Source: SMP Poland Testing Lab, 2020-2021

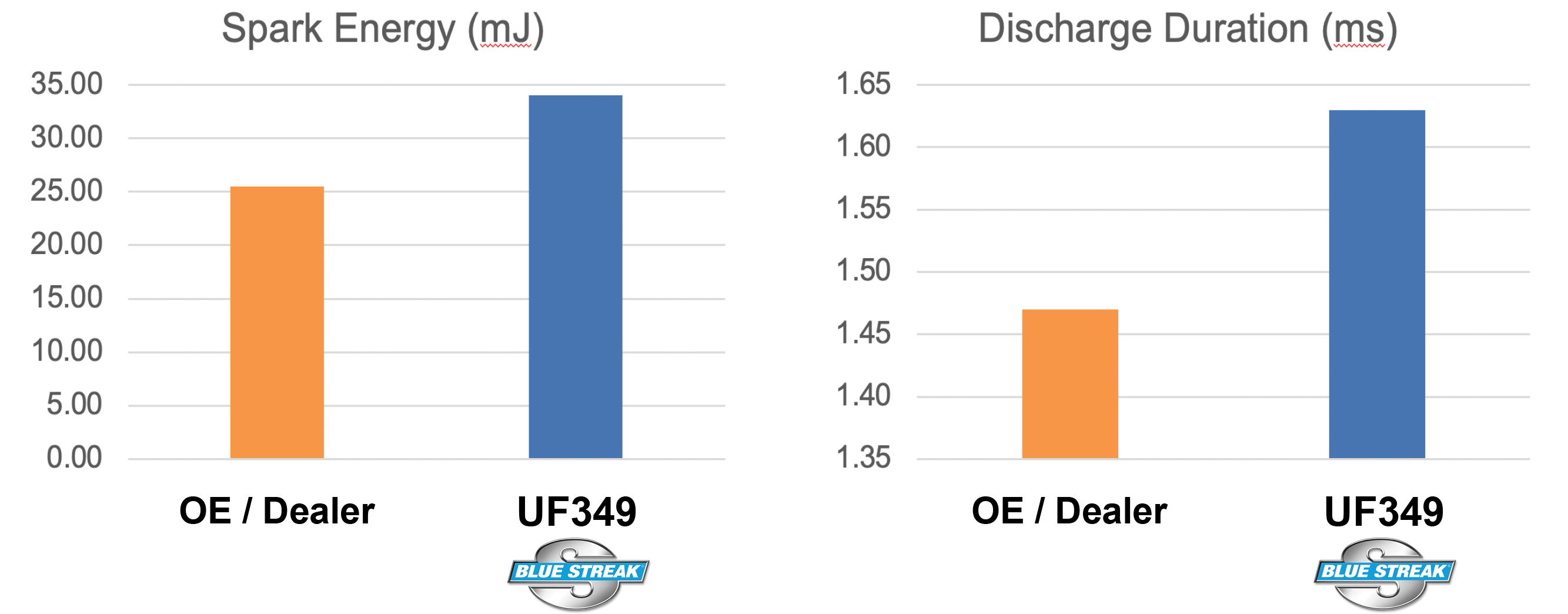

Blue Streak® Outperforms the OE

Blue Streak® coils outperform the OE, producing more spark energy and longer-lasting discharge for improved vehicle performance, fuel economy and emissions. Our SMP Poland Testing Lab conducted a performance comparison between the OE and our Blue Streak® UF-349 import coil. They tested both spark energy and discharge duration.

Let's take a look at the results below:

Testing Results:

-

The Blue Streak® UF-349 produces 22% more spark energy than OE.

-

The Blue Streak® UF-349 has a longer-lasting discharge (11%) than the OE.

Source: SMP Poland Testing Lab, 2020-2021

Made to Perform Under Harsh Conditions

Our SMP Poland engineers subjected our Blue Streak® UF-349 coil and an OE coil to a 200-hour salt spray test. Just like before, the results speak for themselves.

The Blue Streak® coil with an upgraded brass bushing outperformed the OE in the salt spray environmental test with almost no corrosion, while the bushing on the OE coil rusted.

Source: SMP Poland Testing Lab, 2020-2021

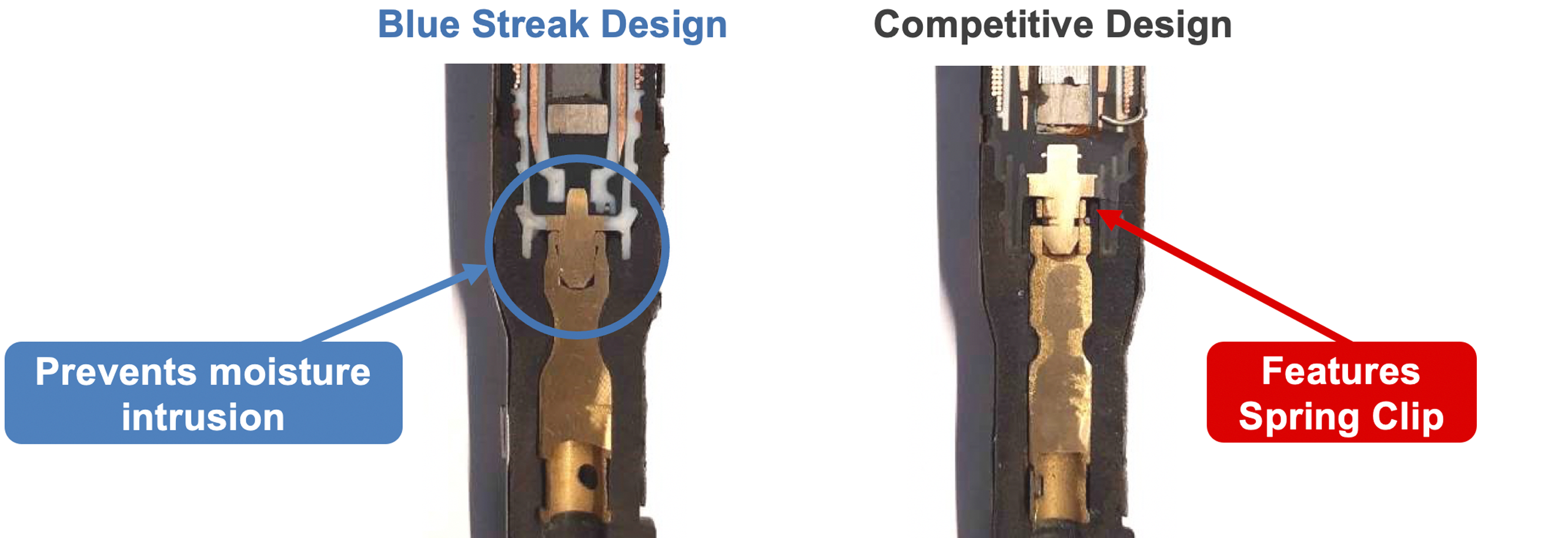

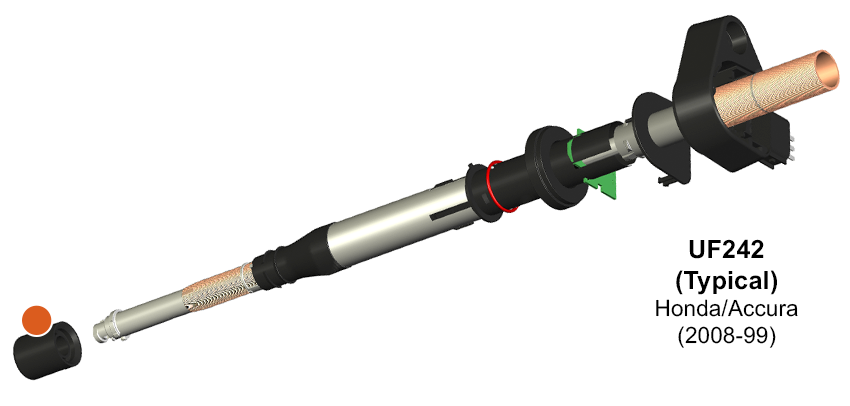

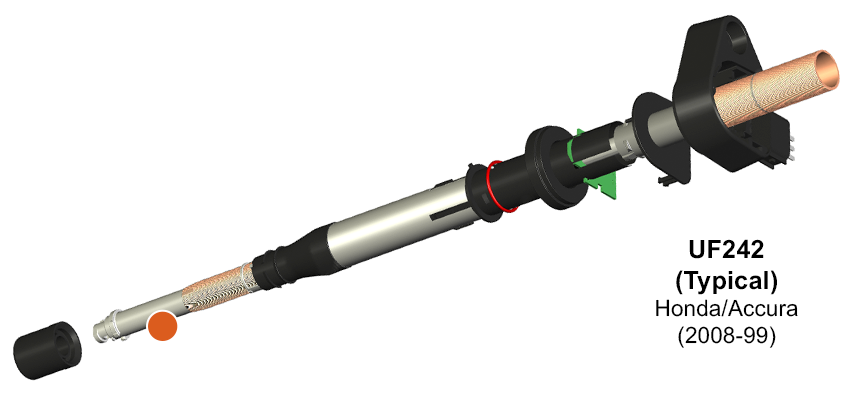

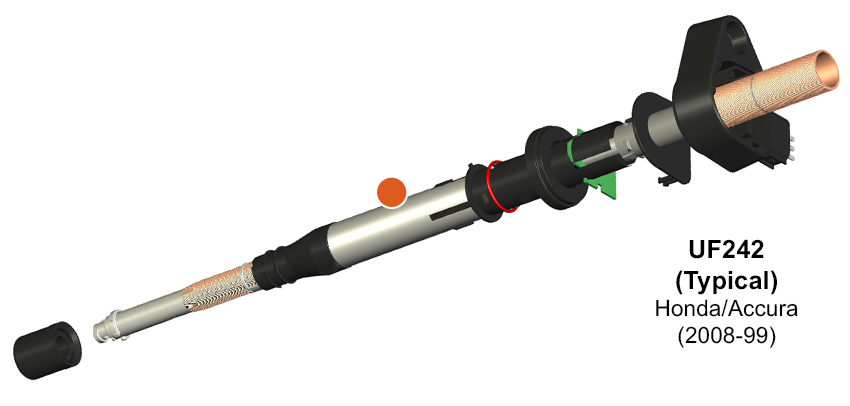

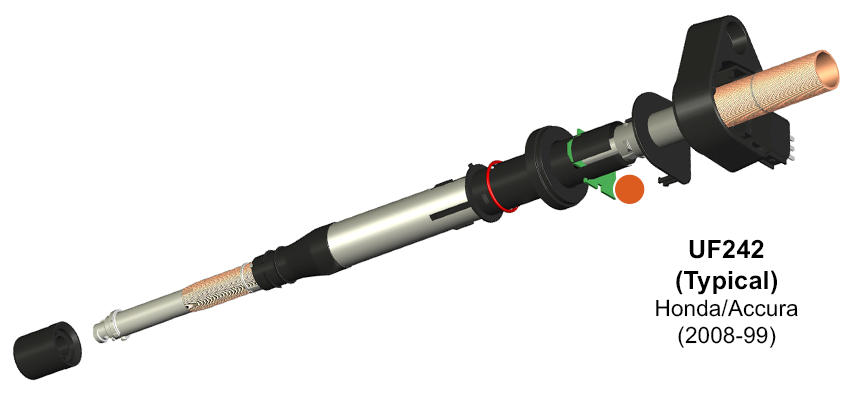

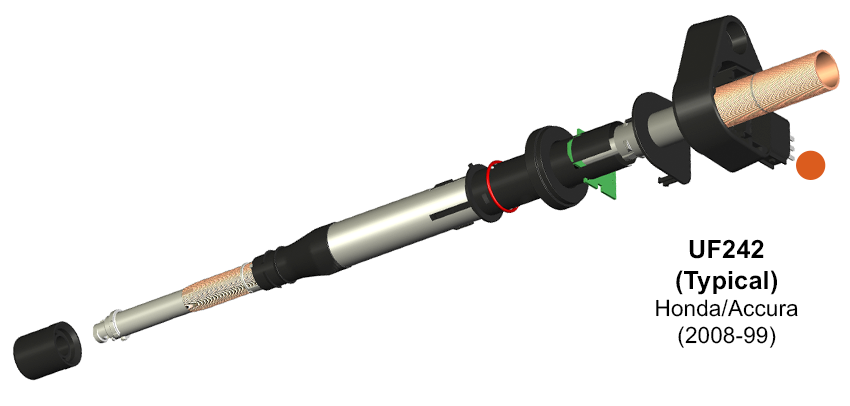

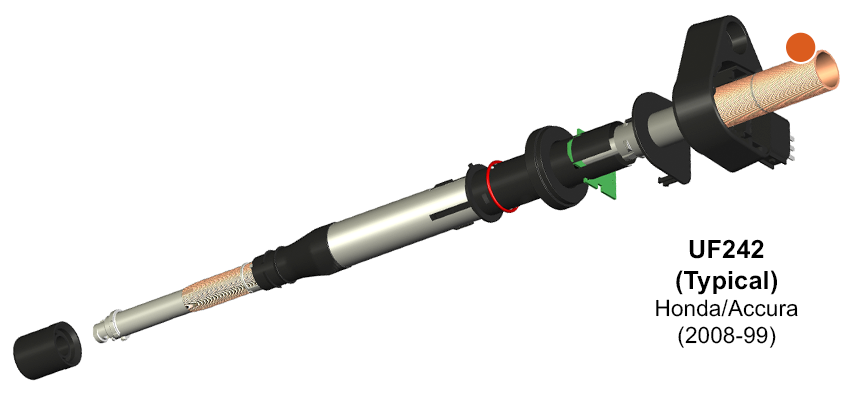

Design Improvements

Blue Streak® engineers made design improvements to numerous OE pencil coils. Take a look at our UF-575 Blue Streak® import coil compared to the competitor design. When you add up all of the Blue Streak® design improvements, the end result is a heavy-duty, longer-lasting import ignition coil that is protected from moisture intrusion.

- The Blue Streak® coil features one-piece housing and simplified press-fit; over-molded secondary terminal prevents moisture intrusion and ensures a secure secondary connection for a long-lasting, high-performing coil.

- Other manufacturers’ two-piece housing and spring-clip design can lead to moisture intrusion, unwanted contact arcing and coil failure.

Source: SMP Poland Testing Lab, 2020-2021

A Better-Performing, Longer-Lasting Coil

The Blue Streak® import ignition coil features more sections. That means less heat and a longer coil life.

How Blue Streak® engineers a better-performing, longer-lasting coil:

- One-piece hi-dielectric strength housing and simplified core separator

- Precision-wound bobbin and more secondary bobbin sections

- Vacuum-injected high-dielectric epoxy and high-temp silicone boot

Source: SMP Poland Testing Lab, 2020-2021

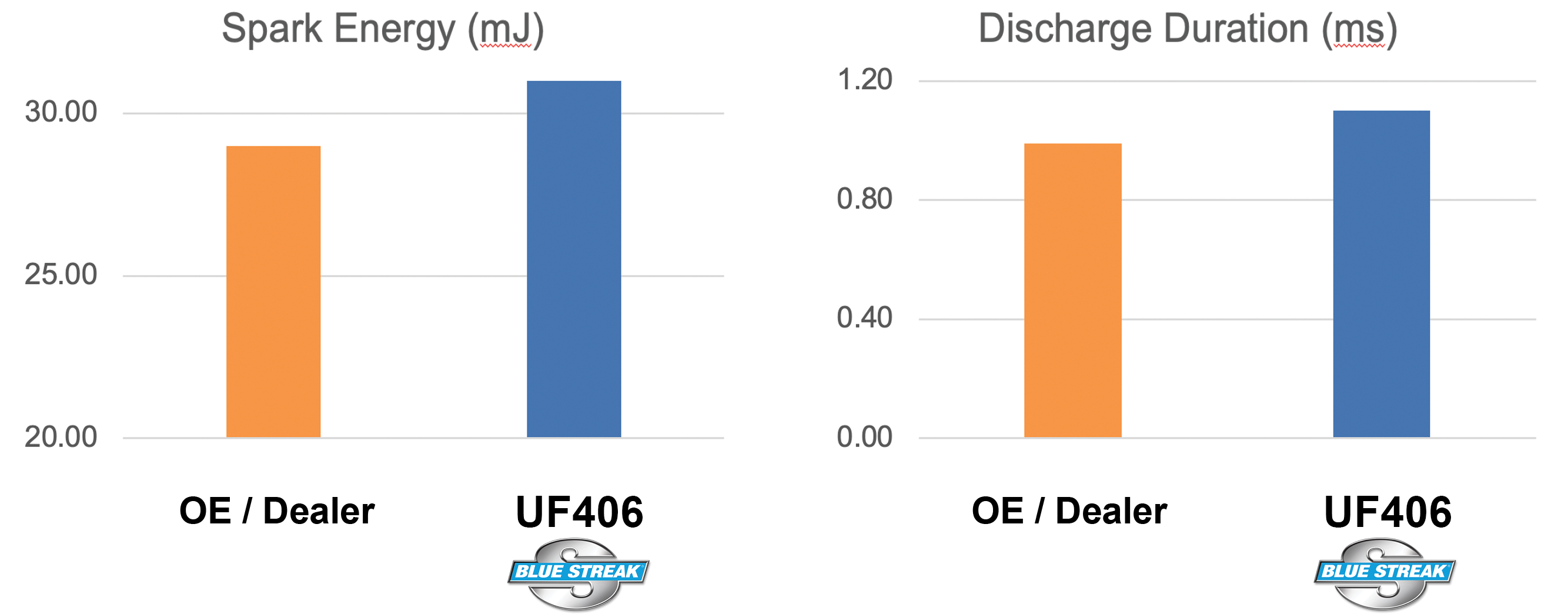

Blue Streak® Outperforms the OE

Our SMP Poland Testing Lab conducted a comparison between the OE and our Blue Streak® UF-406 import coil. They tested both spark energy and discharge duration.

Here is another example of a Blue Streak® import coil outperforming the OE by producing more spark energy and longer-lasting discharge. This results in improved vehicle performance, fuel economy and emissions.

Let's take a look at the results below:

Testing Results:

-

The Blue Streak® UF-406 produces 7% more spark energy than OE

-

The Blue Streak® UF-406 has a longer lasting discharge (11%) than the OE

Source: SMP Poland Testing Lab, 2020-2021

The Blue Streak® Import Advantage

By identifying OE flaws, Blue Streak® is able to improve on the OE design and engineer a more reliable, better-performing, longer-lasting import ignition coil.

-

Silicone rubber boot withstands extreme heat and provides superior insulation

-

Internal core made from grain-oriented electrical steel enhances the magnetic circuit to reduce heat for better coil performance

-

External core made from silicon steel for durability

-

Neodymium magnet produces max high-voltage output at all speeds

-

Electronic ignition module profile and feedback signal matches the original for fit, form and function

-

Tin-plated brass terminals improve electrical contact and protect against corrosion

-

Primary and secondary bobbins made from fiberglass-reinforced polyethylene terephthalate prevent voltage flashover for extended service life