Mass Air Flow Sensor FAQs

If you're replacing a mass air flow sensor (a.k.a MAF sensor) this article provides helpful tips such as how and when to replace them and steps to extend their longevity.

How do you replace a mass air flow sensor?

There are different ways to replace mass air flow sensors (a.k.a. airflow sensors and mass airflow sensors). In this video, our master technician shows you how to replace a full housing-style mass air flow sensor on a 2006 Pontiac Grand Prix. For more videos on mass air flow sensors, view our YouTube Playlist.

When do mass air flow sensors need to be replaced?

Road debris and other contaminants that get past the air filter can coat the mass airflow sensor’s sensing element. The coating insulates the element, causing under-reporting of airflow off-idle and over-reporting of air at low air speeds. GM systems are the one exception to over-reporting of air mass at low airflow speeds.

Often, technicians first try to clean the sensor. Although cleaning a contaminated MAF may seem to bring the performance back, it rarely brings it to 100% operation and accuracy. There are many instances where the internal circuitry is damaged or shorted. In these cases, the sensor needs to be replaced. Because the mass airflow sensor is a key component to the engine’s fueling strategy, it is crucial that the MAF reports with 100% accuracy to ensure peak performance, fuel economy, and reduced emissions.

How does a mass air flow sensor work?

Modern mass air flow sensors use either a hot wire(s) or hot film element. The sensor’s internal circuitry heats up the element to a specific temperature. As air flows past the element and cools it off, the sensor increases the current to the element to maintain the specified temperature.

There is a direct correlation to the amount of current needed to maintain the element’s temperature to the MASS of airflow past it.

It’s important to note that the sensor’s element is only a sample of a small part of the airstream. If the intake system has been modified or changed due to a failure, the element may not receive an adequate sample of incoming airstream, which may cause a measurement error to occur

If air enters the engine without passing through the sensor (for example, the air boot between the intake and the mass air flow sensor isn’t installed properly, or a vacuum leak is present), the true airflow mass entering the engine will not be known.

What does a mass air flow sensor do?

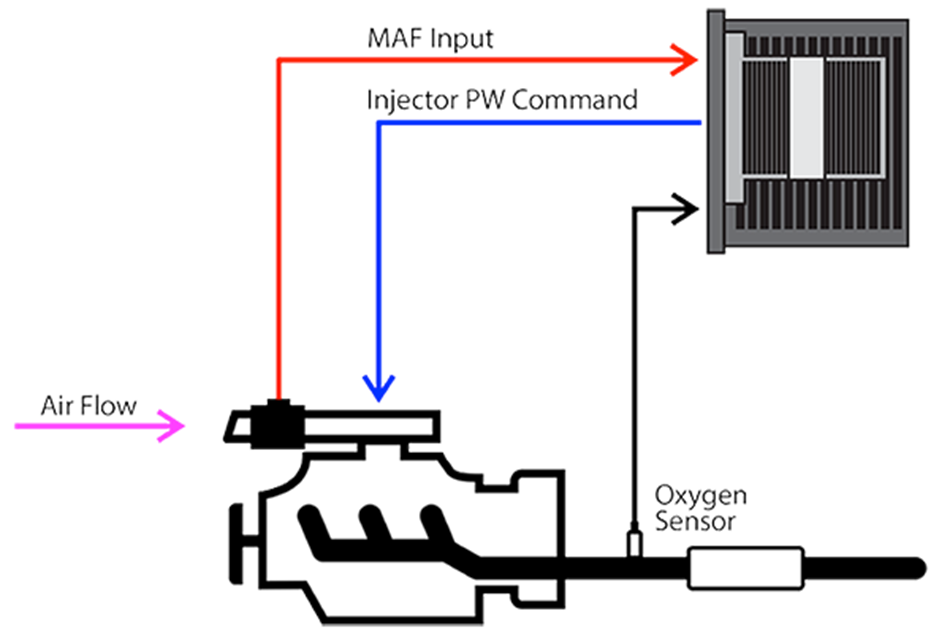

In a mass air flow system, the base fuel calculation is very simple. The ECM receives the air mass value from the mass airflow sensor and then calculates the required injector pulse width to deliver the amount of fuel needed for the desired air/fuel ratio.

Once the requirements for closed loop operation are achieved, the ECM starts with the base fuel calculation and then monitors the oxygen sensor feedback. If the delivered air/fuel ratio is too rich or lean, there will be a fuel trim adjustment applied to the injector duty-cycle. If a vehicle’s mass airflow sensor underestimates airflow, the ECM determines that the mixture is too lean and adjusts fuel trim to compensate.

Engine load information—which is used for things like EGR scheduling, shift timing, and spark timing—also comes from the MAF sensor. Though the air/fuel ratio with a skewed MAF will be compensated by fuel trim, there is no “adjustment” to the engine load information.

MAF sensors require laminar airflow, which occurs when the air flows in parallel layers, with no disruption between the layers. The MAF element only samples a small part of the incoming air stream, so if laminar flow is not present the air measurement and fuel delivery will be incorrect. Some older vehicles have a diffuser installed, but most rely on the air filter design to provide the laminar airflow.

"In the past, I’ve replaced the mass airflow sensor and found that it was worse than the one I removed. What should I do?

There’s nothing more demoralizing for a technician than making a diagnosis, replacing a part, and learning that it didn’t cure the condition. If the technician isn’t confident with their diagnosis, they often chase their tail by going in a different direction and replacing other components.

Enter Standard’s new MAF program. Standard is the only supplier to offer ‘OE or Better’ quality in a full-line NEW MAF program. Plus, Standard is the only aftermarket supplier with U.S. manufacturing. Each SMP-manufactured new MAF sensor is calibrated and tested to ensure 100% accuracy. No more installing a reman unit that has been cut apart and glued back together, and no more tapping it with the handle of a screwdriver and hoping that it works. With Standard’s new MAF sensors, you can feel confident knowing that it will work properly right out of the box.

How can I ensure the longevity of my new mass air flow sensor?

- The first line of defense for a new mass airflow sensor is the air filter. It’s crucial to have a new high-quality air filter installed at the same time as the new MAF.

- Make sure that the air box seals properly, and that there are no obstructions in it. If you’ve attended our Pro Training Seminars, you may remember a case study where a plastic grocery back got sucked into the air box and plugged off the air filter.

- It’s crucial to have an OE-design air filter. Some oiled filters can get over-oiled, which ends up contaminating the MAF sensor and causing worse performance. Some cheaper replacement filters have a different design that alters the airflow direction, thus skewing the reading of the MAF. You may also recall a Ford Explorer case study where an air filter changed the airflow and resulted in skewed MAF, Baro, and Fuel Trim readings.

- Make sure there are no “performance” airflow devices installed in the air intake (like those tornado devices you’ve seen on infomercials). These devices will disrupt the planar airflow that is crucial to accurate MAF readings.