Why Pentastar Oil Filter Housings Fail

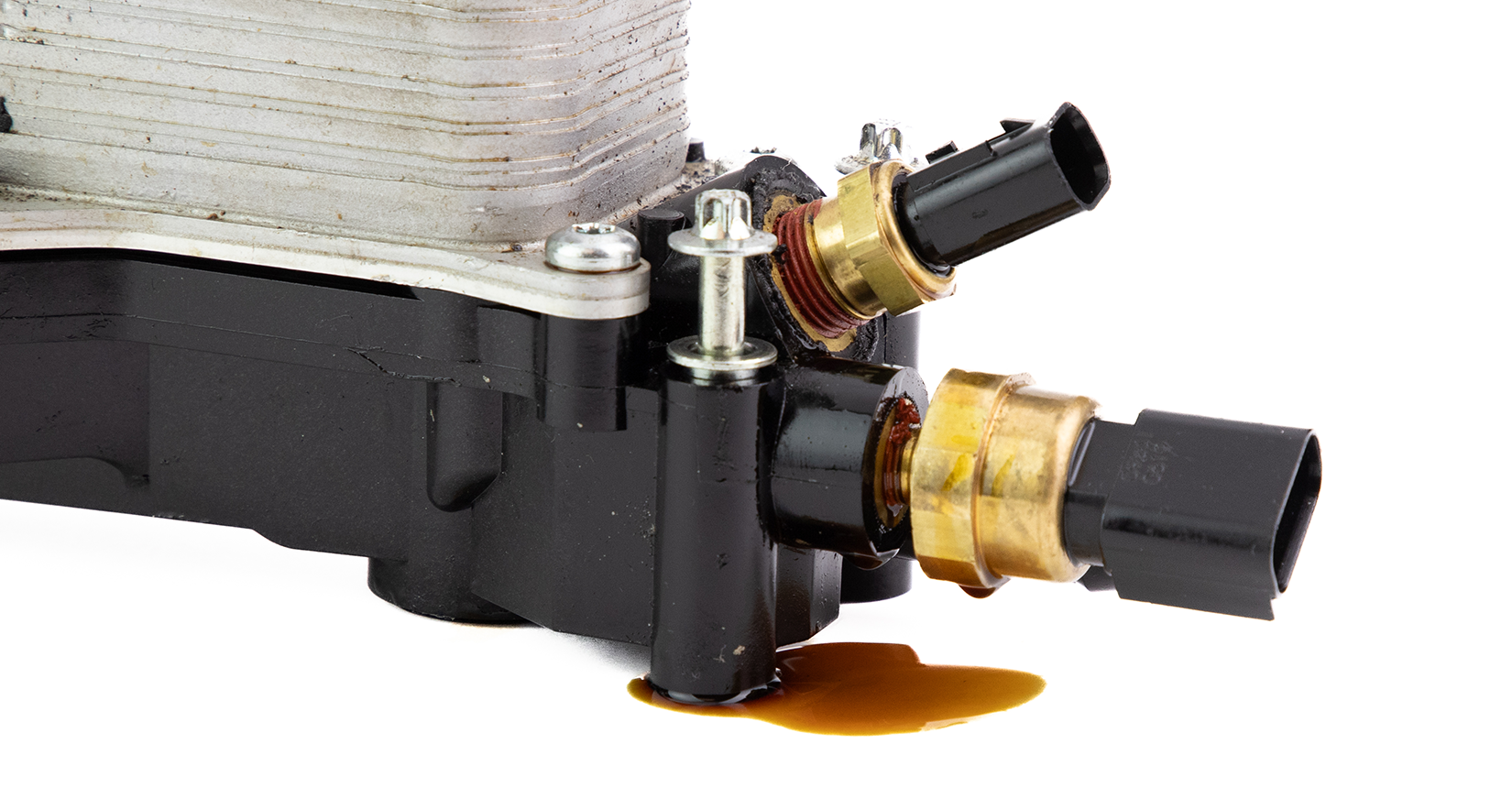

In service since 2011, the Chrysler Pentastar 3.6L engine has powered more than 10 million of the most popular vehicles on the road including the Dodge Challenger, Jeep Wrangler, and RAM 1500. These Pentastar engines are equipped with oil filter housings, which contain the oil filter, sensors, and a heat exchanger to help cool the oil. Like many new OE designs, there have been problems, especially with some of the earliest versions, and the oil filter housings on the Pentastar V6 engine have become known for their high failure rates. These failures have mistakenly been attributed the idea that the housings can warp due to heat, but this has been proven false. So, why do these units typically leak? There are multiple weak points in the original design that can land Pentastar-powered vehicles in service bays.

- Oil leaks around the back of the unit under the filter because the core plugs used to seal the passages do not have any O-rings or seals.

- Oil seeps around the sensors because there is not an adequate seal between the brass sensor insert and the housing itself.

- Oil leaks around the base of the housing because the original seals become easily distorted and fail.

- Oil contaminates the coolant because there is no seal on the internal plug which separates the oil and coolant passages inside the housing.

A new housing with multiple improvements over the original is the best way to help prevent future leaks and get your customer back on the road.

Oil leaks on the OE units because the core plugs are installed without gaskets or O-rings.

Standard® Solutions

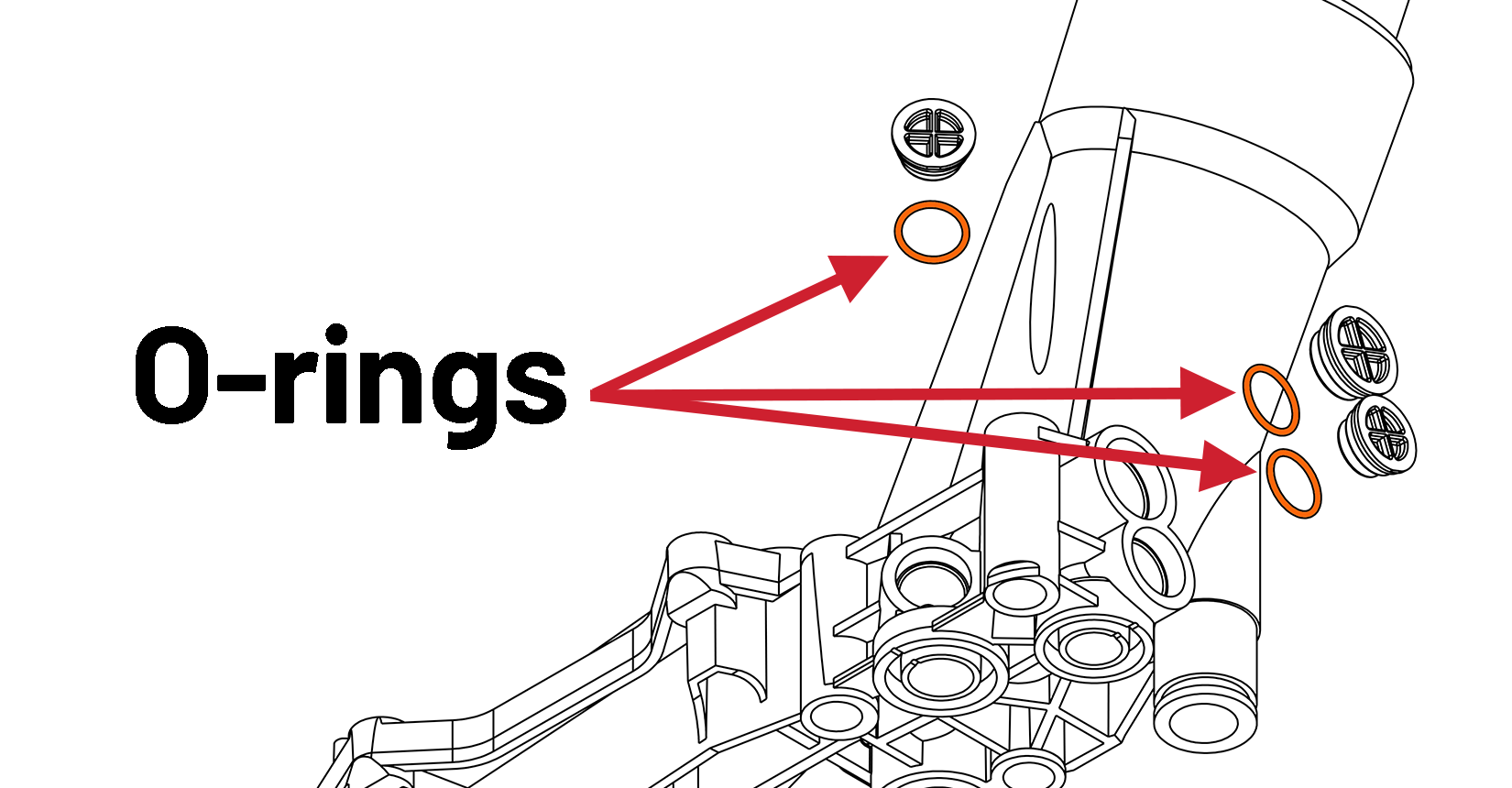

The engineers at Standard® have studied the OE housing failures and created a completely assembled Oil Filter Housing Kit that addresses these issues and prevents leaks. Standard® solutions include the following:

- An O-ring is installed on each core plug on the back of the unit under the filter before ultrasonically welding them into the housing, creating a positive, long-lasting seal.

- Multiple high-temp seals are installed on the knurled brass sensor inserts to prevent oil leaks. Additionally, new oil pressure and oil temperature sensors are installed at the factory and the sensors are correctly torqued in a controlled environment, eliminating the chance of damaging the threads or housing.

- New distortion-resistant seals are installed on the bottom of the housing where it meets the engine. These seals are made from a synthetic material that is less prone to failure than the original.

- A robust seal is added to the core plug separating the oil and coolant passages, preventing internal failure and cross contamination.

Standard® solved the OE problem by installing an O-ring on each core plug before ultrasonically welding them into the housing to prevent leaks.

Beware of Low-Quality Replacements

In addition to simply recreating the original design without improvement, many aftermarket replacement units typically come bare, requiring the technician to transfer the coolant fittings, sensors (oil pressure and temperature), oil cooler, oil filter, cap, and bypass valve. Many times, the coolant fittings and sensors will be damaged in the removal process. This transfer requires a fair amount of labor, and in the repair bay, time is money.

Standard® Oil Filter Housing Kits

Oil filter housings on Pentastar V6 engines may all look similar, but there are distinct differences from year to year, including different sensors, oil filters, flow rates, and lack of a temperature sensor on late-model applications. Because of this, Standard® has designed and manufactures five different oil filter housing kits for Pentastar engines, with each one including OE-matching sensors and an oil filter with the correct flow rate. Standard® Oil Filter Housings come assembled from the factory and include everything needed for a complete and correct installation. The oil filter and cap are an exact OE-match and are already installed. Additionally, all Standard® assemblies include a new oil temperature sensor, a new oil pressure sensor (where required), gaskets, seals and hardware so you won’t have to reuse any of the old, worn pieces.

Standard® Oil Filter Housings are assembled and ready for installation; a true quality drop-in solution.

For more information on replacing these units, search “Oil Filter Housing Assembly” on the Standard Brand YouTube channel.